The Advanced Materials Laboratory (AML) is one of seven laboratories that comprise Sandia’s Materials Science and Engineering Center. The AML has expertise in the development of materials and coatings for marine renewable energy and provides...

The Advanced Power Electronic Conversion Systems (APEX) Laboratory supports the development of advanced power conversion topologies and intelligent control strategies. Research in the APEX laboratory focuses on robust and fault-tolerant conversion systems for utility-scale...

Bioscience is one of Sandia's research foundations, an area considered key to the success of the Lab's national security programs. In the Applied Bioscience Laboratory (ABL) at Sandia California, the bioscience research focus is...

The Atmospheric Radiation Measurement (ARM) Climate Research Facility, a Department of Energy scientific user facility, provides the climate research community with strategically located, in situ, and remote sensing observatories. This facility is designed to improve...

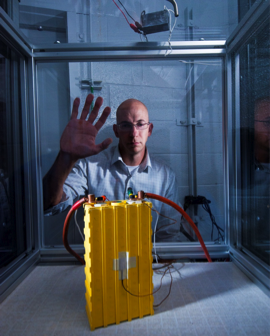

The Battery Abuse Testing Laboratory (BATLab) at Sandia is an internationally recognized leader in energy storage system safety research. The BATLab is committed to serving the energy storage community and the national interest with cutting-edge research...

Using the Nuclear Energy Systems Laboratory (NESL) / Brayton Lab, Sandia National Laboratories is creating a thermal-to-electric power conversion technology in a configuration called the recompression closed Brayton cycle (RCBC) that uses supercritical carbon dioxide...

Carlsbad Sandia acts as the scientific advisor to the Department of Energy’s Waste Isolation Pilot Plant (WIPP) repository project for WIPP regulatory compliance and recertification. Carlsbad Sandia’s geochemistry work is primarily laboratory-based, with focused research...

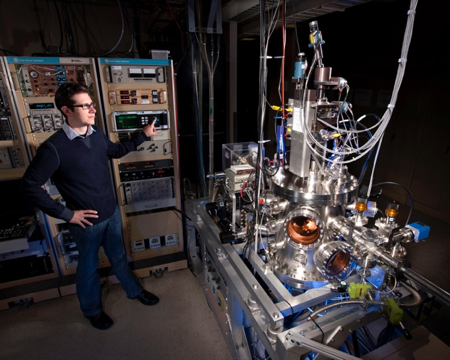

The Center for Integrated Nanotechnologies (CINT) is a Department of Energy/Office of Science Nanoscale Science Research Center operating as a national user facility devoted to establishing the scientific principles that govern the design, performance, and integration...

Established as the first Department of Energy user facility in the 1970s and designated as a DOE collaborative research facility in 2008, the Combustion Research Facility (CRF) has served as a national and international leader in...

The Computer Science Research Institute (CSRI) brings university faculty and students to Sandia for focused collaborative research on Department of Energy computer and computational science problems. CSRI focuses on research in areas of computer...

Researchers at the Control and Optimization of Networked Energy Technologies (CONET) Laboratory conduct research, development, and testing on networked and distributed systems. Research at CONET is interwoven with cybersecurity objectives and focuses on: coordinated communications, controls...

Sandia’s Distributed Energy Technologies Laboratory (DETL) is a multipurpose research facility designed to integrate emerging energy technologies into new and existing electricity infrastructure to accommodate the nation’s increasing demands for secure and reliable energy. Utilizing the...

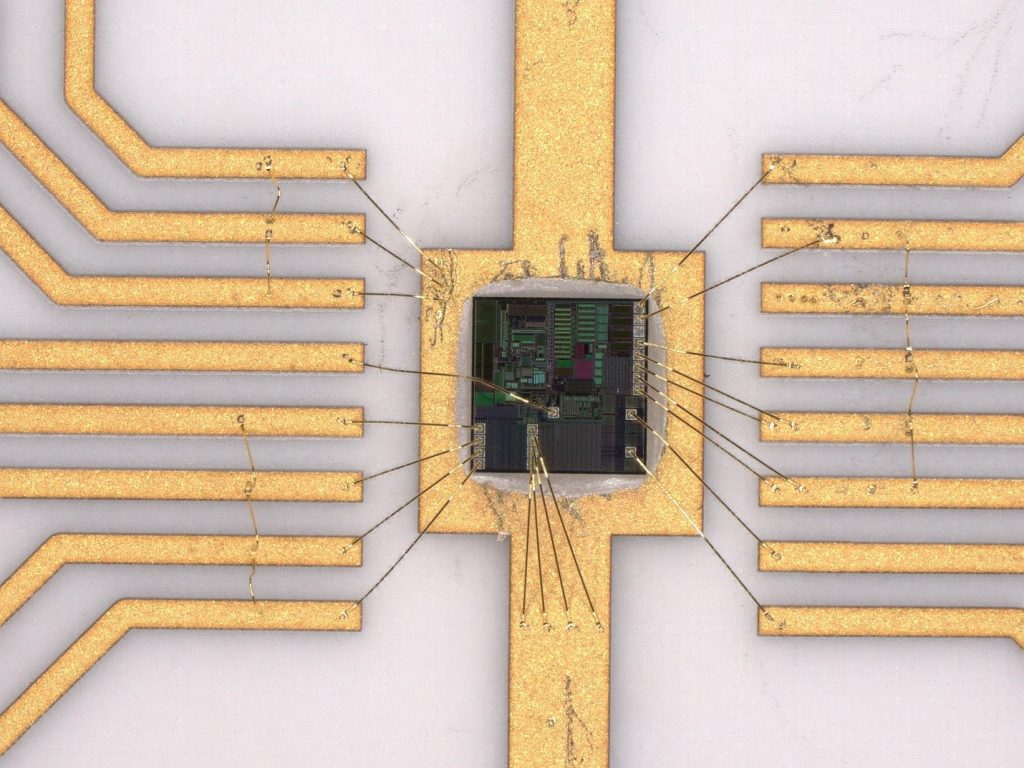

The Electronics Development Lab offers capabilities for high temperature electronic fabrication and assembly, the evaluation of electromagnetic hardware, optical evaluation, 3D printing, and long-term storage of sensitive electronics while under electro-static protection. Image depicts...

The Energy Storage Test Pad (ESTP), in conjunction with the Energy Storage Analysis Laboratory (ESAL), provides long-term testing and validation for electrical energy storage systems. Sandia also provides pre-certification, pre-installation, and verification of energy storage systems....

The Sandia FACT Site provides the equipment and seismically quiet surroundings required for testing infrasound and seismic sensors, instrumentation, and monitoring systems. This site allows for geothermal tools to be tested with a wireline truck to...

The Geochemistry Laboratories at Sandia support the investigation of basic scientific questions including material behaviors at mineral-fluid interfaces and the effects of chemical environment on fracture. Experimental geochemistry studies allow researchers to build and...

The Geomechanics Laboratory allows its users to measure rock properties under a wide range of simulated service conditions up to very high pressures, elevated temperatures, and complex load paths. The laboratory's capabilities make it...

A large plot of land, known as Tech Area III, allows Sandia’s geothermal research program to evaluate large systems. For example, the program has 1,000 feet of drilling pipe that was used for evaluating...

Sandia maintains a large laboratory facility for the development, assembly, and testing of geothermal technologies. Sandia’s evaluation and assembly facility provides several testing, processing, and packaging stations and capabilities for high-temperature packaging, high-temperature and...

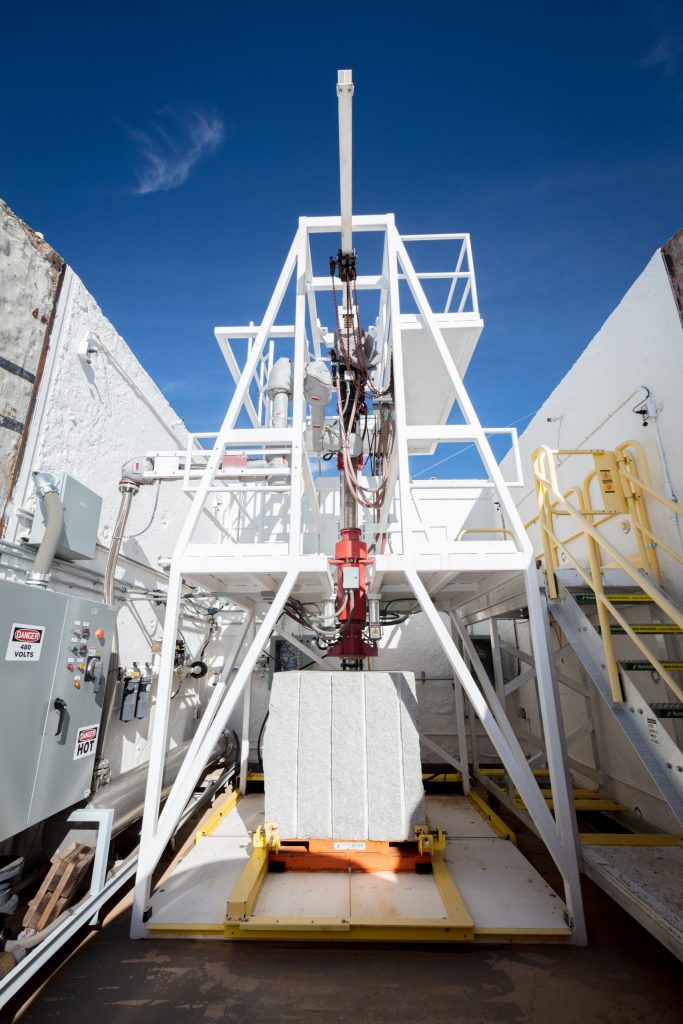

Geothermal resources are typically associated with igneous and metamorphic rocks, which are harder than the sedimentary rocks through which most oil and gas wells are drilled. The Hard Rock Drilling Facility features a vertical...

Sandia’s High Operating Temperature (HOT) Facility houses a 20-foot-tall drill rig, heating chamber, and process gas heater. HOT can simulate conditions deep underground by elevating the temperatures directly to the drill bit and can...

The technical staff at Sandia National Laboratories have access to High Performance Computing (HPC) Production Clusters for solving, visualizing, and interpreting large, complex science and engineering problems. Currently there are 4 such Linux clusters...

The Hydrogen Effects on Materials Laboratory is the cornerstone of Sandia’s research expertise in hydrogen compatibility of materials and a core capability stewarded by the Office of Energy Efficiency and Renewable Energy’s (EERE) Hydrogen and Fuel...

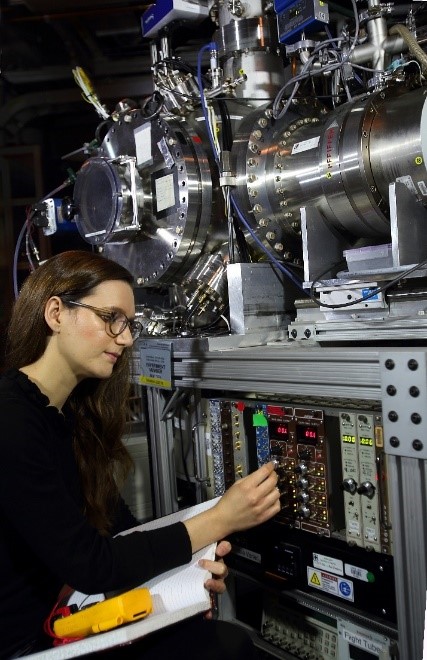

Sandia’s Hydrogen–Surface Interactions Laboratory includes an array of specialized capabilities assembled to address the obstacle of directly detecting hydrogen in furthering our understanding of hydrogen–surface interactions. The lab includes an angle-resolved ion energy spectrometer...

Sandia staff in the Hydrogen Transport and Trapping Laboratory evaluate many features of the interactions between hydrogen and materials. In particular, the effects of hydrogen on mechanical properties can be strongly influenced by transport (or diffusion)...

The Joint BioEnergy Institute (JBEI) is a San Francisco Bay Area research partnership that combines scientific expertise, resources, and support of four national laboratories, five academic institutions, and one industry partner. Led by Lawrence Berkeley National...

Current speed and wave measurements are critical for assessing the resource and hydrodynamic characteristics at an MHK site. Sandia’s team has the capability and sensors/instrumentation for conducting field- and laboratory-scale measurements, such as ADCPs,...

The Microsystem Assembly and Brazing Facility offers advanced capabilities for epoxy die bonding, soldering, wire bonding, seam sealing, holistic packaging and materials process analysis, metal deposition (e.g., PVD, CVD, ALD), 3D printing (e.g., PEEK,...

The Microsystems Engineering, Science, and Applications (MESA) Complex integrates the numerous scientific disciplines necessary to produce functional, robust, integrated microsystems and represents the center of Sandia’s investment in microsystems research, development, and prototyping activities. Visit the...

Sandia created the Mobile Instrumentation Data Acquisition System (MIDAS) to provide on-site data acquisition and analysis capabilities for testing of radioactive and hazardous materials packages. MIDAS allows researchers, designers, and regulators to examine and understand how...

The National Infrastructure Simulation and Analysis Center (NISAC) is a modeling, simulation, and analysis program within the Department of Homeland Security comprising personnel in the Washington, D.C., area, as well as from Sandia National...

Operated by Sandia for the U.S. Department of Energy (DOE), the National Solar Thermal Test Facility (NSTTF) is the only large-scale concentrating solar power (CSP) and solar thermal test facility in the United States. The primary...

The Nuclear Energy Work Complex (NEWC) consists of two separate facilities: Surtsey and the Cylindrical Boiling facility (CYBL). Surtsey acts as the base of operations for the Nuclear Energy Work Complex and includes a...

Sandia’s Photovoltaic Systems Evaluation Laboratory, or PSEL, provides expertise and test support within several facilities and outdoor sites for evaluating PV and other distributed energy technologies. It includes the following capabilities: PV systems evaluations...

Manufacturers of solar technologies partner with the Regional Test Centers program to have the performance of their products validated at one or more of six climatically distinct sites in the United States, including locations...

The Water Power Technologies department leverages these capabilities in robotics to support wave energy converter (WEC) design and testing. Visit the Robotics website

The Sandia Wave Energy Power Take-off (SWEPT) Laboratory offers mobile, specialized testing for systems that produce power from wave energy. SWEPT is used to test wave energy converter (WEC) power take-off (PTO) systems. WECs are unique...

Scaled Wind Farm Technology Facility (SWiFT) Sandia National Laboratories’ Scaled Wind Farm Technology Facility in Lubbock, Texas, was a state-of-the-art public research and training facility funded by the U.S. Department of Energy. SWiFT partnered...

The Thermal Test Complex (TTC) is an international resource for validation of fire physics models as well as the nuclear weapons complex hardware qualification facility for fires. Experimental fire research, validated modeling tools, and phenomenological model...

Sandia and the University of Alaska Fairbanks (UAF) have teamed up to advance the concept of a permanent, comprehensive multi-agency U.S. High Arctic Research Center (USHARC) in the Prudhoe Bay area. Sandia and UAF are actively...