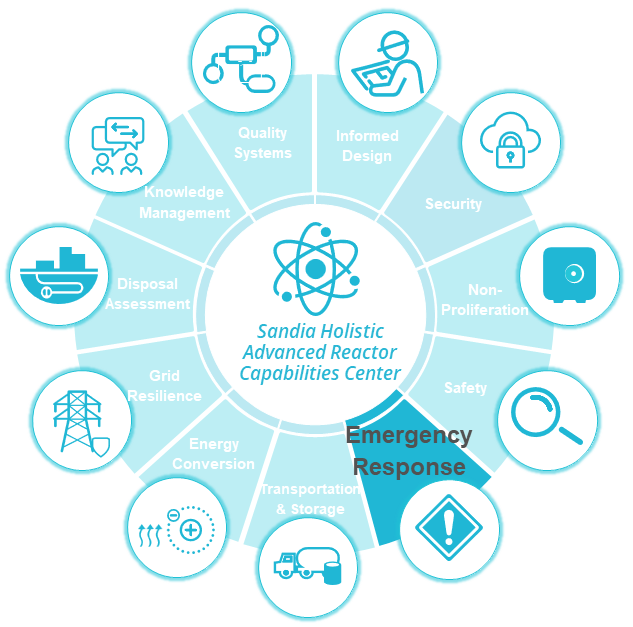

Sandia develops innovative technologies and methodologies through scientific analyses and experiments to enhance the safety of the nuclear fuel cycle and the supporting infrastructure. We provide a scientific basis to support Nuclear Regulatory Commission (NRC) licensing and regulatory decisions and advance the technical foundation for severe accident analysis/management and high consequence risk characterization of light water and advanced nuclear power systems. In addition, we provide and advance the scientific and technical basis to defend energy systems from cyber and physical threats. Furthermore, we provide and advance the scientific and technical basis for assessing the environmental, economic, and human health impacts of an accident at a power plant.

We contribute value to our partners by bringing over forty years of experience supporting the NRC with nuclear energy science and engineering expertise which is augmented by decades of expertise in nuclear weapons safety and security. The nuclear energy work at Sandia is augmented by the ability to leverage the many state-of-the-art unique testing and computational facilities.

View more information about Sandia’s nuclear facility risk assessment capabilities.

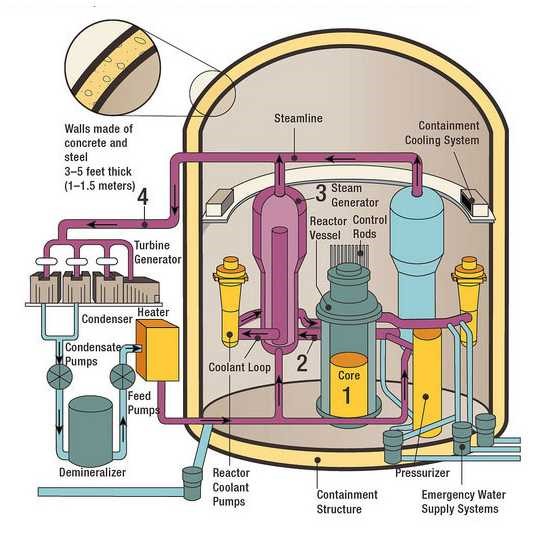

Severe Accident Modeling and Analysis

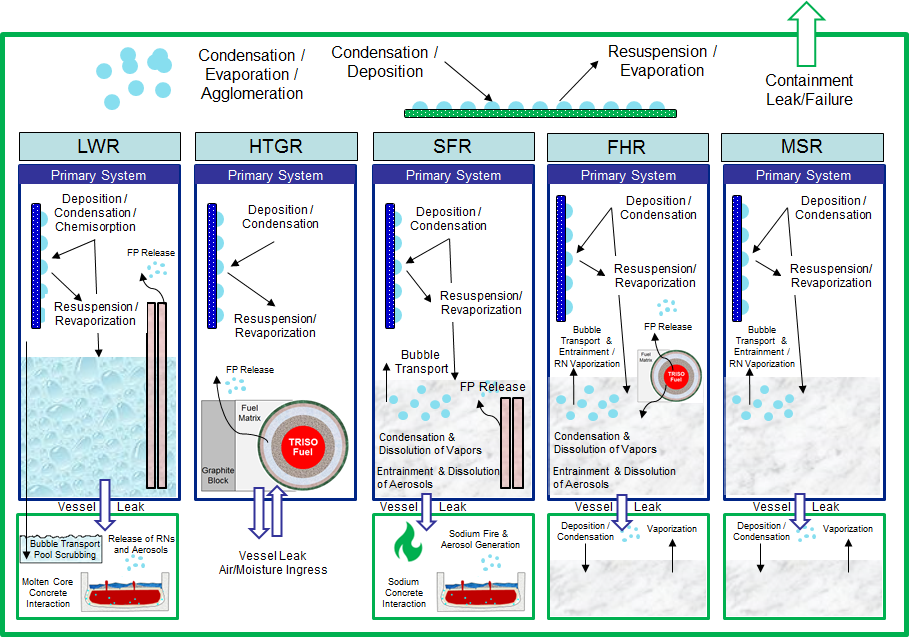

Sandia develops nuclear reactor safety technology in support of the U.S. and international nuclear energy sectors. The MELCOR software was developed to analyze nuclear power reactor accidents that could lead to release of radiation to the environment. The software enables assessment of the potential for consequences to public health and safety.

The research and development initiatives at Sandia are leading significant reactor safety technology innovation. We develop:

- Modern accident analysis software – MELCOR

- Advanced machine learning methods to enable next generation risk-informed safety assessment methods

The broad range of physical phenomena modeled by MELCOR has enabled its application to a range of engineering analyses beyond traditional nuclear power plant accident analysis. These include:

- Assessment of fusion systems

- Transport of contaminants within buildings

- DOE radiological facility safety assessments

MELCOR is reactor safety technology of national and international significance.

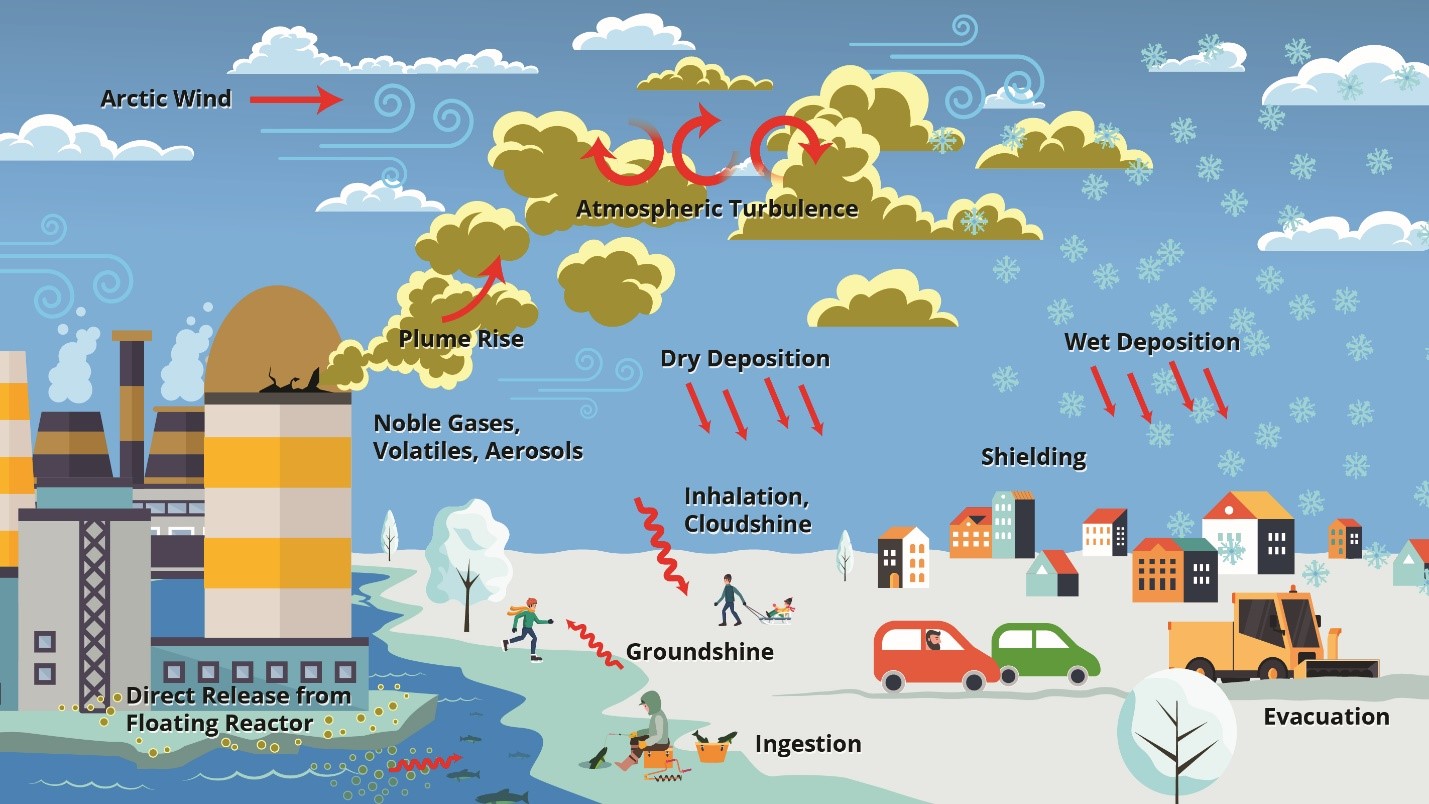

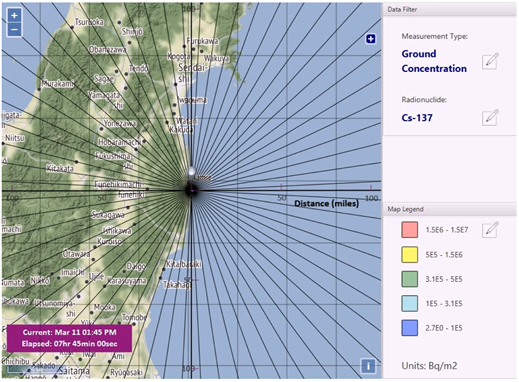

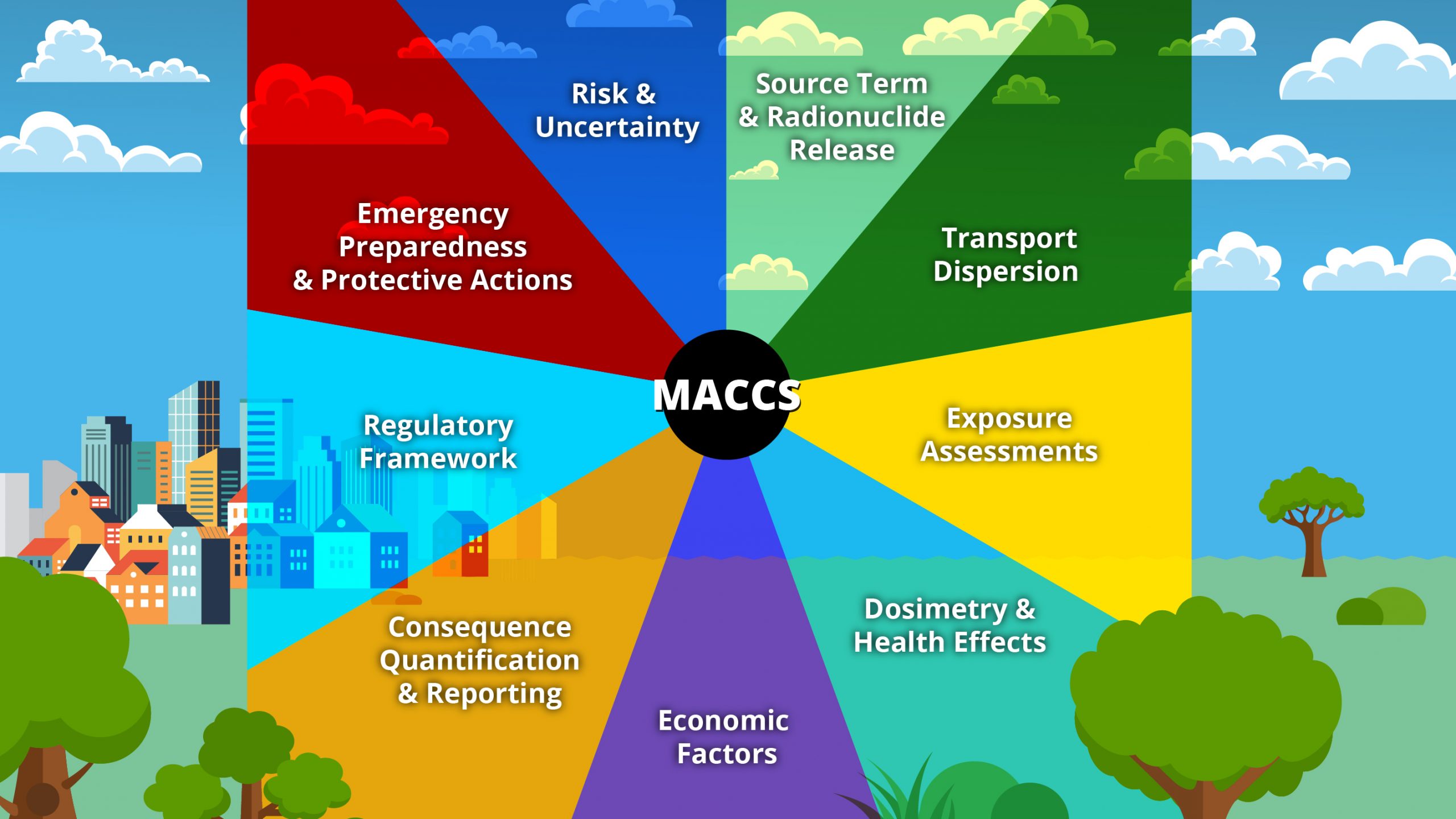

Accident Consequences Modeling and Analysis

Sandia leverages expertise in atmospheric transport modeling, health physics and dosimetry, aerosol sciences, emergency planning and response, economics, and nuclear engineering to form multidisciplinary teams to address a wide range of problems.

Researchers use this expertise to examine:

- Advanced modeling capabilities to support Advanced, Micro-, and Small Modular Reactors

- Support the deployment of reactors in unique environments such as the Arctic

- Consequence analysis for severe accidents involving nuclear power plants, nuclear facilities, and chemical/biological applications. This analysis uses state of the art computer codes to model atmospheric transport and assess both health and economic impacts following a release of harmful substances into the atmosphere.

- Probabilistic and risk informed analysis for nuclear energy systems and facilities.

- Development of software frameworks and applications that enable understanding of the full range of environmental, economic, and human health impacts. State-of-the-art computer codes developed by Sandia on behalf of the U.S. Nuclear Regulatory Commission include MELCOR Accident Consequence Code System (MACCS).

- Support of decision makers and emergency response personnel in reacting to the environmental release of radioactivity by any mechanism or means.

- Nuclear reactor design and regulatory processes.

- Launch safety analysis for radioisotope thermoelectric generators and space-based reactors.

(click on images to enlarge)

High Consequence Risk

Sandia provides research, design, development, and implementation of risk methodologies for high consequence systems including light water reactor nuclear power plants and other emerging technology areas (e.g., advanced reactors, microreactors, hydrogen generation, natural gas). Recent development of risk methodologies includes the dynamic PRA tool ADAPT and development of methods to systematically analyze hazards and consequences of digital systems. Sandia’s work in advanced reactors and reliability has led to the creation (or recreation) of a database for sodium system components called NaSCoRD. Our core competencies include probabilistic risk assessment, analysis of human reliability, system reliability, fire analysis, consequences, and digital instrumentation and controls. Sandia’s state-of-the-art modeling and simulation, experimental capabilities, and data collection allow for deep scientifically based exploration of experimental consequences.

(click on images to enlarge)

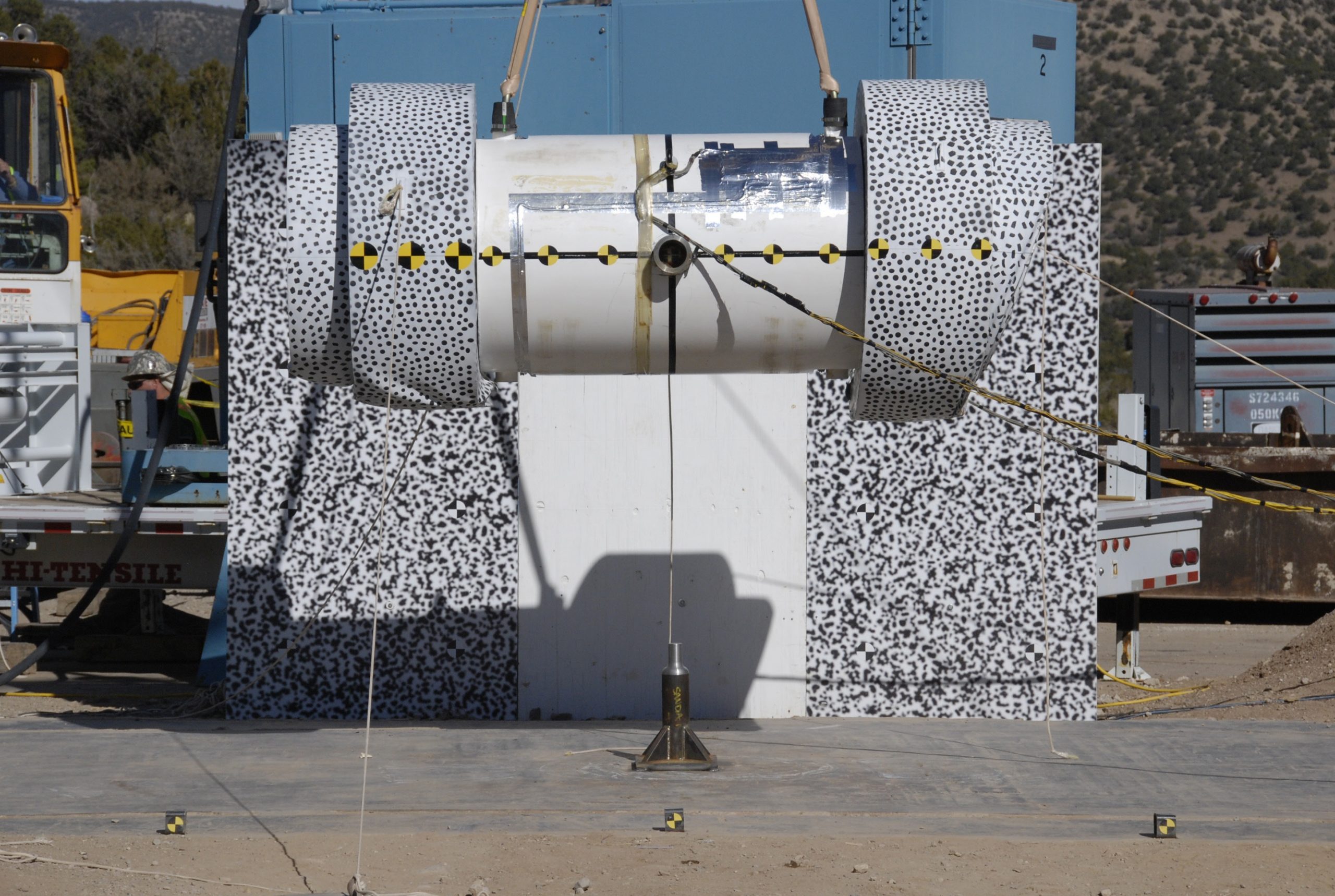

Containers Packaging and Transportation

Sandia has extensive expertise in containers, packaging, and transportation of nuclear materials. This expertise includes a full spectrum of capabilities from design, analysis, and testing at different scales (from bench scale to full scale), certification testing, technology and materials development, quality assurance, safety analysis reports and reviews, transportation risk assessments, and package logistics and utilization modeling. Sandia has a fully NQA-1 compliant mobile data acquisition system called MIDAS that can be used in certification testing. Sandia also supports training in package development, testing, and certification.

Systems, Structures, and Materials

Sandia provides technical depth and support needed across the nuclear energy program. We provide materials research and development and conduct analyses of the performance of systems, materials, and components for the current fleet of commercial nuclear power and advanced reactor designs. Leveraging the extensive testing and experimental facilities at Sandia, we also conduct experiments to collect data used to validate single- or coupled-physics computational models for structural, thermal, fluid dynamics, and materials applications. Computational validation is enabled through Sandia National Laboratories’ high performance computing (HPC) resources. Sandia and the National Nuclear Security Administration’s (NNSA) Advanced Simulation and Computing (ASC) program have built a legacy of developing and deploying innovative HPC systems central to national energy security missions.

Major areas of research and development within this area include:

- eXtremely Low Probability of Rupture (xLPR) – A probabilistic fracture mechanics (PFM) computational capability, developed in collaboration with NRC and Electric Power Research Institute (EPRI), to assess the structural integrity of piping systems in nuclear power plants subjected to the effects of Primary Water Stress Corrosion Cracking (PWSCC).

- Advanced materials testing research – Material degradation research is conducted at the Center for Integrated Nanotechnologies (CINT) in support of piping and pressure vessel applications. CINT research has focused on developing means to understand the mechanical, thermal, and chemical effects influencing subsurface fluid flow over a range of length scales.

- Aging of concrete containments – Investigation of the performance of concrete containment vessels, degradation and failure modes, enhancements to computational prediction of structural behavior, and evaluation of inspection and the monitoring of pre-stressing systems inclusive of non-destructive evaluation techniques (NDE) and by using sensors.

(click on images to enlarge)

Contact

Richard Griffith

(505) 844-8232

rogrif@sandia.gov

Facilities

Annular Core Research Reactor (ACRR) and Gamma Irradiation Facility (GIF)

Core melt experiments

Accelerated irradiation aging of materials

National Solar Thermal Test Facility (NSTTF)

Molten Salt Test Loop

Heat pipe research

Cylindrical Boiling Facility (CYBL)

Spent fuel pool fires

Dry cask simulators

Nuclear Energy Systems Laboratory (NESL) & Brayton Laboratory

Advanced power conversion cycle research

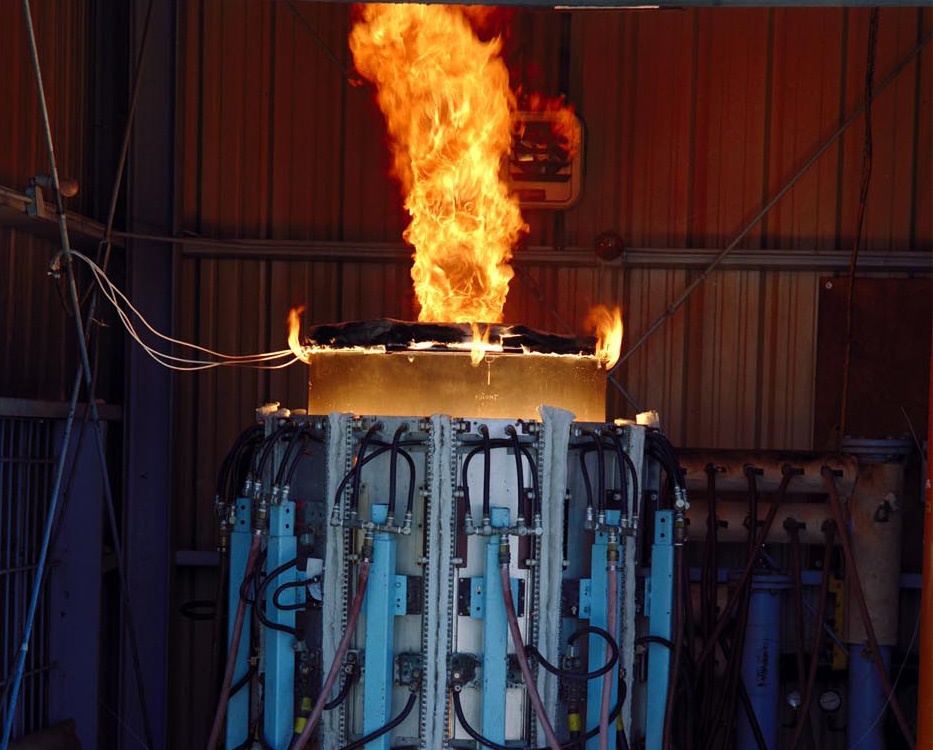

Surtsey

High-energy reactor and containment accidents

Sodium coolant fires