Sandia’s program in subsurface energy storage connects our expertise in underground energy storage with researchers and developers in commercial, industrial, and academic settings. Together, we are building national expertise in wellbore integrity for oil, gas, and carbon storage, as well as geologic hydrogen and hydrogen storage.

Our combined experts, facilities, drilling technology, and cement seal research make Sandia a leading research and development institution for the subsurface storage of hydrogen, helium, compressed air, natural gas, and oil products—including the identification and repair of existing well bores.

- We conduct research to understand the current state of both legacy wells and currently operating wells. This includes educating on current integrity issues, understanding the mechanisms for loss of integrity, and working towards learning how to protect those assets, both from an engineering aspect and a regulatory aspect.

- We also apply our knowledge and understanding of underground storage to other industries developing new energy storage methods.

Sandia has been the geotechnical adviser for the Strategic Petroleum Reserve (SPR), the world’s largest supply of emergency crude oil, for 40 years. We are responsible for characterizing the site, which includes cavern and well development, geomechanical analysis, ensuring the integrity of caverns and wells, subsidence, and monitoring. Sandia’s many subsurface capabilities enable us to support the major changes that are taking place at SPR in terms of life extension programs and the possibility of more dynamic fill/withdrawal operations.

Sandia’s expertise, coupled with drilling technology and cement seal research, makes Sandia capable of leadership roles in subsurface storage for hydrogen, helium, compressed air, natural gas, and oil products, including the identification and repair of existing well bores.

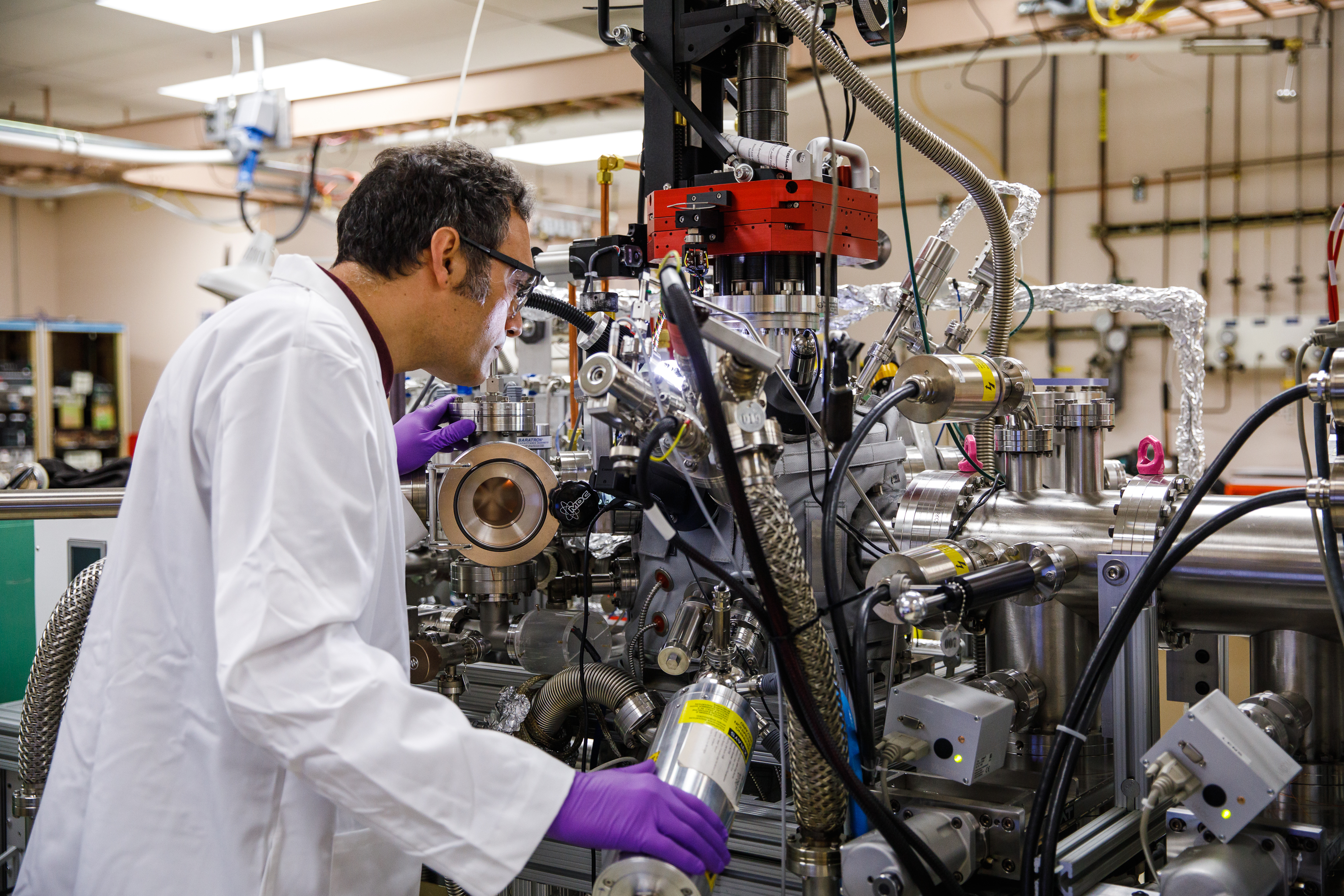

Sandia’s team completes subsurface rock testing

One of four SPR Salt Dome sites

Typical wellhead configuration for the SPR caverns

Projects

Sandia was asked to review the kill well procedure during the Aliso Canyon natural gas storage well leak. In response to the Aliso Canyon gas leak, Sandia was involved in helping to develop new state regulations, using science to ensure that well integrity is monitored. We are also reviewing the Aliso Canyon Root Cause Analysis as Subject Matter Experts and analyzing workplans for geologic, seismologic, and geomechanical hazards at the site.

Sandia teams with commercial partners to offer operational decision-quality modeling and analysis for cavern stability and dome-wide impacts of new cavern emplacement.

Sandia is responsible for establishing testing, certification, and monitoring procedures for, and predicting the long-term behavior of the SPR.

Sandia’s work for the SPR consists primarily of the following technical activities:

- Underground Storage of Crude Oil

- Site Planning of Storage Facilities

- Site Characterization Studies

- Brine Disposal

- Cavern Integrity Monitoring and Testing

- Well Integrity Monitoring and Testing

- Subsidence Modeling

- Microseismic Analysis & Other Monitoring Technologies

- Oil and Brine Chemistry

- Full Cavern/Well Design and Development

- Cavern Operational Analyses

- Robust Geomechanical Modeling

Investments

- Extensive modeling capabilities

- Field scale testing and employment: Development and deployment of a high-temperature and high-pressure chemical sensing downhole tool. Used for in-situ fracture connectivity mapping, high-temperature electrochemistry, and real-time pH measurements

- Large rock mechanics testing laboratory: Capable of running triaxial stress and strain tests on rock and other materials, along with long-term temperature-controlled creep tests

- Subsurface characterization in three-dimensions and in time

- Subsurface sensors: Design and deployment of sensors and subsurface wireline tools

- CAVEMAN

- Monitoring code that offers real-time cavern leak monitoring based on detection of other-than-expected wellhead pressures

- SIERRA SOLID MECHANICS ADAGIO CODE

- Performs mechanical modeling calculations on Sandia’s High Performance Computing systems

- Kayenta

- A computational framework for generalized plasticity models

- PFLOTRAN

- Aims to solve a system of generally nonlinear partial differential equations describing multiphase, multicomponent, and multiscale flow and transport in porous materials with multiphysical features

- SANSMIC

- A salt solution mining code used to aid in the development of salt caverns

- SIERRA/ADAGIO

- Sandia-developed 3D solid mechanics code used as a solver for salt mechanical behavior; ADAGIO uses the SIERRA Framework, which allows for coupling with other SIERRA mechanics codes

CAVEMAN test results

High-performance computational modeling

SANSMIC test results

Future

In addition to providing technology support to the SPR, Sandia works with industry and academic partners in the planning, development, and operation of underground salt caverns for the storage of liquid and gaseous hydrocarbons. Our focus is onsite planning, geological investigations, cavern and subsurface mechanics, wellbore integrity, oil chemistry, operational analyses and salt leaching analyses while also providing project support in materials, multi-phase fluid flow, engineering, turbulence/shock analysis and other areas of expertise.

We will continue to support the SPR, our partners, and industry by:

- Completing direct subsurface measurements through precise micro-drilling

- Advancing downhole sensing for wellbore integrity

- Providing wellbore risk assessment expertise

- Advancing extensive geomechanical modeling capabilities for industry

- Conducting spatial and geostatistical analyses

- Conducting energy system resiliency analyses focusing on security and disaster recovery

- Engineering capabilities for process plant simulation and pressure-volume-temperature modeling of gases and liquids, including underground storage

- Monitoring and repair of damaged cement-geomaterial interfaces in high pressure high temperature repository and borehole scenarios (Sandia, University of New Mexico, and University of Texas at Austin partnership)

- Working with federal regulators, namely the Pipeline and Hazardous Materials Safety Administration (PHMSA), on reliability of subsurface safety valves in underground natural gas storage and regarding tubing and packers lifecycle for unattended ground sensor applications (Sandia and Battelle Memorial Institute partnership)

- Advancing detection of wellbore failure for safe and secure utilization of subsurface infrastructure (Sandia, University of New Mexico, Battelle Memorial Institute, and Chevron partnership)

Publications

-

Hart, D. (2023). 2023 Annual Report of Available Drawdowns for Each Oil Storage Cavern in the Strategic Petroleum Reserve. https://doi.org/10.2172/1973473 Publication ID: 80950

-

Moriarty, D. (2022). Strategic Petroleum Reserve Enhanced Monitoring Compendium (FY 2022). https://doi.org/10.2172/1901695 Publication ID: 80451

-

Potter, C., Moussa, J., Wilcox, A., Gilbert, L., Vargas, V., & Vargas, V. (2022). General Overview of Mobile Sources Used for Well Logging and Industrial Radiography Applications. https://doi.org/10.2172/1901988 Publication ID: 80454

-

Montoya, R. (2022). Shifting from Fossil Fuel Reliance to Green Energy Sovereignty: Ute Mountain Ute Tribe. https://doi.org/10.2172/1900359 Publication ID: 80443

-

Bainbridge, J., Claussen, N., Iivanainen, J., Schwindt, P., & Schwindt, P. (2022). High-Sensitivity rf Detection Using an Optically Pumped Comagnetometer Based on Natural-Abundance Rubidium with Active Ambient-Field Cancellation. Physical Review Applied, 18(4). https://doi.org/10.1103/physrevapplied.18.044052 Publication ID: 80216

-

Rodriguez, S. (2022). Computational Fluid Dynamics and Heat Transfer Modeling of a Dimpled Heat Exchanger. https://doi.org/10.2172/1893993 Publication ID: 80383

-

Stofleth, J., Crocker, R., Tribble, M., & Tribble, M. (2022). V31 Test Report. https://doi.org/10.2172/1895026 Publication ID: 80400

-

Kearney, S., Swain, W., Stacy, S., Halls, B., wwerik, W., Marinis, R., Richardson, D., Marsh, A., Mazumdar, Y., & Mazumdar, Y. (2022). Quantifying Thermal Output of Energetic Materials (LDRD Final Report). https://doi.org/10.2172/1892464 Publication ID: 80373

-

Wang, M., Guo, X., Zhang, S., Xiao, L., Mishra, U., Yang, Y., Zhu, B., Wang, G., Mao, X., Qian, T., Jiang, T., Shi, Z., Luo, Z., & Luo, Z. (2022). Global soil profiles indicate depth-dependent soil carbon losses under a warmer climate. Nature Communications, 13(1). https://doi.org/10.1038/s41467-022-33278-w Publication ID: 80289

-

Ho, T., Wang, Y., & Wang, Y. (2022). Carbon dioxide-enhanced metal release from kerogen. Scientific Reports, 12(1). https://doi.org/10.1038/s41598-022-19564-z Publication ID: 80160

-

Baird, A., Hecht, E., Ehrhart, B., Muna, A., & Muna, A. (2022). Liquid Hydrogen Heavy-Duty Vehicle Safety Review and Refueling Facility Design. https://doi.org/10.2172/1885100 Publication ID: 80124

-

Mishra, U., Gautam, S., & Gautam, S. (2022). Improving and testing machine learning methods for benchmarking soil carbon dynamics representation of land surface models. https://doi.org/10.2172/1891184 Publication ID: 80258

-

Frederick, J., Conley, E., Nole, M., Marchitto, T., Wagman, B., & Wagman, B. (2022). Quantifying the Known Unknown: Including Marine Sources of Greenhouse Gases in Climate Modeling. https://doi.org/10.2172/1889332 Publication ID: 80268

-

Yoon, H., Kucala, A., Chang, K.W., Martinez, M.J., Bean, J.E., Kadeethum, T., Warren, M., Wilson, J., Broome, S., Stewart, L., Estrada, D., Bouklas, N., Fuhg, J., & Fuhg, J. (2022). Computational Analysis of Coupled Geoscience Processes in Fractured and Deformable Media. https://doi.org/10.2172/1890064 Publication ID: 80248

-

Zeitler, T., Ross, T., Valdez, R., Maurer, H., Hart, D., & Hart, D. (2022). Strategic Petroleum Reserve Cavern Leaching Monitoring CY21. https://doi.org/10.2172/1886118 Publication ID: 80144

Contact

Don Conley

(505) 845-3555