Our approach to enable micro reactors and small modular reactors (SMRs) combines smart microgrid technology, High Performance Computing (HPC), Advanced Manufacturing (AM) and Supercritical Carbon Dioxide (sCO2) Brayton Cycle advanced energy conversion system.

Sandia has 15 years’ experience designing, and performing sCO2 Brayton Cycle experiments, with the goal of increased thermal performance.

Supercritical Transformational Electric Power (STEP) Nuclear Energy

Sandia’s supercritical carbon dioxide (sCO2) Brayton Cycle

What is sCO2

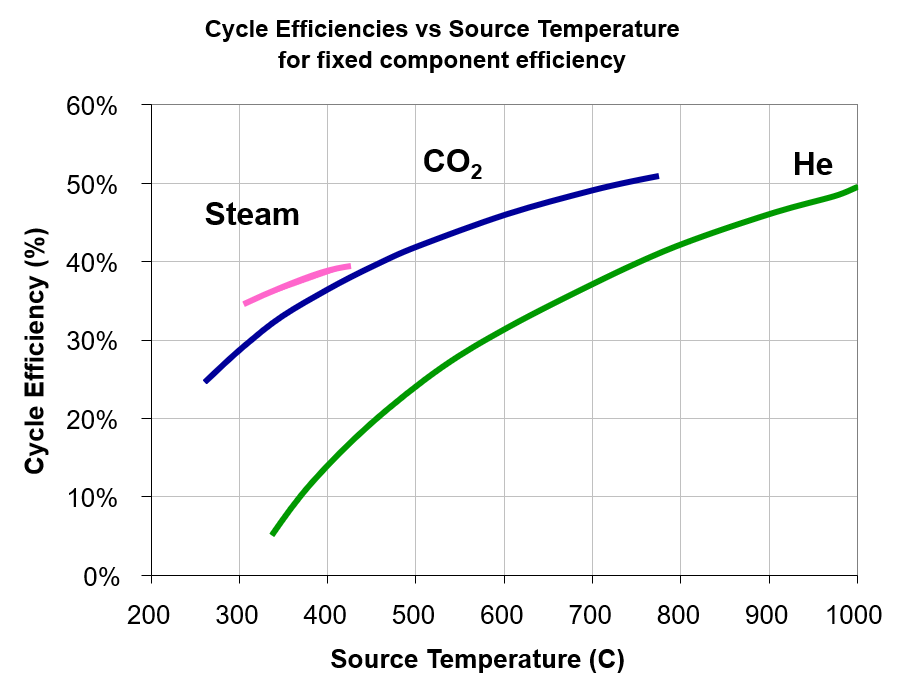

sCO2 is a fluid state of carbon dioxide where it is held above its critical point (i.e., critical pressure and temperature). The density at that point is similar to that of a liquid and allows for the pumping power needed in a compressor to be significantly reduced, thus significantly increasing the thermal-to-electric energy conversion efficiency.

Sandia is researching a thermal-to-electric power conversion technology in a configuration called the recompression closed Brayton cycle (RCBC) that uses sCO2 as the working fluid, rather than steam, thereby dramatically increasing conversion efficiency compared to the steam Rankine cycle.

The primary reason for improved power conversion efficiency is simply that the use of sCO2 as the working fluid in a Brayton cycle requires less work to convert a given thermal input to electricity. In general, increased efficiency represents increased output for the same thermal input, regardless of the thermal source (natural gas, nuclear, solar or coal). Where fuel costs are a significant portion of overall costs (coal and natural gas fired plants), the benefit is reduced fuel costs. Where capital investments are high (nuclear and concentrating solar power), the benefit is increased output for the initial investment.

sCO2 energy conversion technology offers a number of benefits over competing cycles including:

- Smaller size relative to steam system (reduced capital cost)

- Increased efficiency (resulting in increased electricity production for same thermal input)

- Environmental improvement from greenhouse gas reduction

- Vastly reduces water consumption

- Dry cooling/suitable for arid environments

In concert with the Department of Energy, Sandia has been conducting research and development to deliver a technology that is ready for commercialization. Ongoing activities in support of this goal include:

- Confirm viability of existing components (bearings and gas seals) and suitability of materials

- Accommodate a wide range of operating parameters and applications

- Integrate and scale up existing technologies into a new application

- Develop robust operating procedures for operating at critical point

sCO2 energy conversion cycles are potentially applicable to a wide variety of power-generation applications besides nuclear power; some of these other applications include: concentrated solar thermal, fossil fuel boilers, geothermal, and shipboard propulsion systems have all been identified as favorable applications for sCO2 cycles as potential replacements for traditional steam Rankine cycles.

As a first step in facilitating Fossil Energy applications, an operational RCBC can:

- Supplement existing Rankine cycle plant power generation by capturing waste heat energy without disrupting the original power block;

- Replace the steam generating Rankine cycle in coal plants, waste incinerators, and natural gas plants with a 50% improvement in efficiency; and

- Be included in a combined-cycle gas turbine power plant, the combined efficiency can exceed 60%, with reduced total capital cost.

Industry Collaboration

Sandia’s Brayton cycle uses sCO2, which is chemically stable, reliable, low cost, non-toxic, non-flammable, and readily available, as the working fluid. In 2017 Sandia signed three-year Cooperative Research and Development Agreements (CRADAs) with Peregrine Turbine Technologies of Wiscasset, Maine; Xdot Engineering and Analysis of Charlottesville, Virginia; and Flowserve Corp. of Irving, Texas to further development of the sCO2 research.

CRADAs such as these provide an avenue to engage industry one-on-one regarding critical needs and help identify a pathway to commercialization of a game-changing technology.

Sandia has been testing various components, bearings, seals, and heat exchangers near or exceeding the critical point where carbon dioxide has the density close to a liquid but many properties of a gas. Tests showed several elements of the system were at a low technical readiness level (TRL), a measure of technology maturity.

Sandia posted Federal Business Opportunities ads seeking industrial partners, and Peregrine, Xdot, and Flowserve were among multiple respondents.

Peregrine is working with Sandia on a thermally compliant heat exchanger that can handle the Brayton cycle’s rigorous thermal stresses, Xdot is developing a foil bearing that supports a turbine shaft spinning at high speed in sCO2, and Flowserve’s high-intensity seal for power turbines is designed to hold tight with sCO2 going into the turbine at 700 degrees C and 4,400 pounds per square inch, or psi.

In industry the Brayton technology can use solar, biofuels, and natural gas to produce electricity for the distributed energy market. Sandia is working through the three CRADAs with manufacturers who will bring Brayton technology to market, U.S. produced, manufactured and exportable.