Sandia draws on materials science, risk assessment, pipeline, and rail safety experience to create new approaches for pipeline inspection, repair, and optimization. Our research examines safe rail transportation of oil and its many byproducts, fire safety for pipelines and plants, and cybersecurity for all forms of the fossil energy infrastructure.

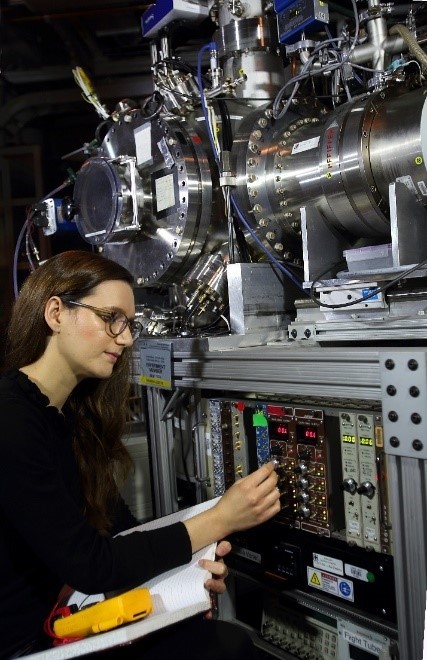

Rebecca Caravan, Sandia postdoctoral appointee, adjusts the Sandia Multiplexed Photoionization Mass Spectrometer that was used to conduct research on volatile organic compounds.

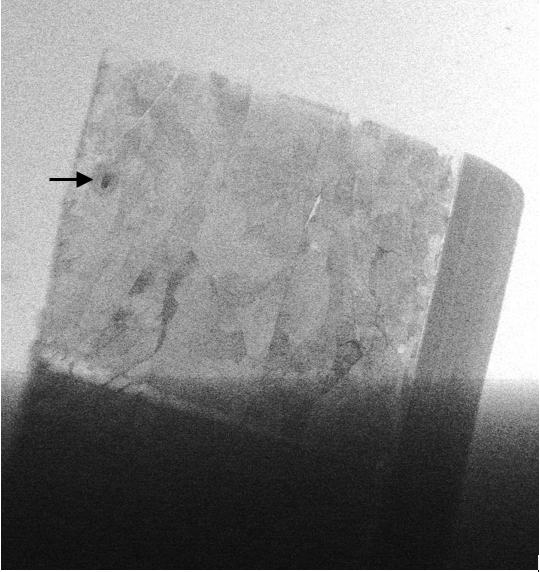

In-situ corrosion of low-carbon steel. (Hayden et al., 2019)

CINTs environmental TEM

Projects

Sandia is developing a predictive computational framework which integrates the various processes controlling atmospheric stress corrosion cracking to evaluate the structural integrity of welded canisters used for storage of spent nuclear fuel. Models for degradation processes include computational sub-models describing:

- Site-specific corrosive environments (temperature and humidity)

- Site-specific deposition of chloride-containing aerosol particles,

- Pit formation

- Pit-to-crack transition

- Crack propagation

This capability is used to guide inspection and mitigation programs of welded canisters and assess the structural integrity of welded canisters stored at interim storage facilities across the nation.

Sandia was responsible for an experimental study exploring whether crude oils produced from “tight” formations in the U.S. and Canada exhibit chemical, physical, and combustion properties that are measurably different than oils produced from “conventional” reservoirs. The main purpose of this study was to determine how crude oil properties associate with thermal hazards in pool fires and fireballs that could result from accidents during transportation of crude by rail. The results from this study inform debate and improve industry best practices in crude oil sampling, analysis, hazardous material classification, and emergency response for large-scale transportation of crude oil in North America.

This project engages the natural gas industry and research community to identify recent relevant technical advances, clarify sensor cyber security needs, and understand and leverage related activities. This effort is intended to produce a clear understanding of the opportunities, needs, and existing efforts within industry.

Sandia will propose a research roadmap to address cyber-attack concerns in the natural gas pipeline systems. This roadmap may include vulnerability identification and security testing using simulation, current or proposed assets, and equipment with real-world attack methods.

Key impacts of this effort will enable us to address attack scenarios, create a prioritized list of potential cyber exploitation/attack sensors suitable for the system, and research and development options for developing automated, scalable sensing and control systems for real-time monitoring.

Sandia is developing a probabilistic method to assess the structural integrity of piping systems in nuclear power plants subjected to the effects of Primary Water Stress Corrosion Cracking (PWSCC). Holistic probabilistic fracture-based mechanics (PFM) computational capabilities were developed to quantify and assess the effects of uncertainties associated with active degradation mechanisms.

This computational capability will be used by nuclear power plant licensees to inform and guide enhanced inspection and mitigation programs to lessen the impact of PWSCC on piping system integrity and comply with federal regulation.

Utilization of the xLPR computational capability enables improvement of safety decision making and regulatory efficiency. The approaches applied to quantification and assessment of piping flaws in nuclear applications can be applied analogously to oil and gas midstream pipelines.

Drawing on our expertise in liquefied natural gas (LNG), computational fluid dynamics, and high-performance computing, Sandia is currently evaluating the Fire Dynamics Simulator open source code for the National Institute of Standards and Technology (NIST). This research will estimate hazard distances for dispersion and pool fires on land and will help develop model evaluation protocol for LNG fires.

This project focuses on characterizing pipeline materials in their relevant operating environments. By using state-of-the-art environmental electron microscopy techniques, we can observe site-specific nanoscale imaging of localized corrosion processes in industrially relevant 1018 carbon steel during exposure to a flowing, aqueous CO2 solution.

Future work will involve combined environmental, thermal, and mechanical testing with atomic scale resolution and fast imaging. Project findings and observations represent an important step toward atomically defining nanoscale corrosion mechanisms, enabling the informed development of next-generation inhibition technologies and validation of predictive models.

Safety Codes and Standards Projects

This project is completed through a partnership with Air Liquide and the Fuel Cell Technology Office and has two areas of research:

- To perform a benchmarking of Sandia’s Hydrogen Risk Assessment Models (HyRAM) toolkit, which conducts quantitative risk assessment, hazard, and consequence analysis.

- To develop a diagnostic tool for capturing three-dimensional (3D) data for large scale hydrogen experiments (CRADA with Air Liquide and FCTO)

The overall project goal is to provide technical assistance to Department of Energy, Clean Cities coordinators, Clean Cities stakeholders, and advanced technology end-users to address these technical challenges and bring advanced transportation technologies to market using Sandia’s depth in applied science and engineering. The project has three focus areas:

- Develop reduced-order engineering models of compressed natural gas (CNG)/liquified natural gas (LNG)/propane release behavior

- Evaluate key risk scenarios in order to develop best practices and code revisions

- Develop educational materials and inform code committees of risk mitigation strategies. Sandia will expand the hydrogen risk assessment tool (HyRAM) to include other alternative fuels including CNG, LNG, and liquefied petroleum gas (LPG) into a new AltRAM toolkit.

The Federal Railroad Administration (FRA) has received several requests regarding approval to transport liquified natural gas (LNG) by train. Sandia is conducting a review on fixed facility risk assessment methods and acceptability criteria applicable to hazardous material transportation.

The technical goal of the project is to cooperatively engage in analytical studies, research, and development on a diverse set of energy-related and hydrogen technology topics. This research will capitalize on Sandia’s hydrogen behavior model and quantitative risk assessment methodology to demonstrate a performance-based approach to a hydrogen refueling station design. This work is completed in partnership with FirstElement Fuel.

Sandia is currently providing support to Department of Energy and Department of Transportation offices to help tunnel owners and authorities with jurisdiction make decisions regarding tunnel access for alternative fuel vehicles including hydrogen, propane, and natural gas. This support includes a literature survey, compilation of experimental data, and modeling and analysis to answer questions about potential consequences for different accident scenarios.

This research agreement with the Fuel Cell Technology Office utilizes Sandia’s hydrogen behavior models and Quantitative Risk Assessment methodology to improve code requirements for hydrogen fuel cell vehicle repair garages. This work begins with a hazard and operability study risk analysis to identify key hydrogen release scenarios for indoor repair garages and then uses the Hydrogen Risk Assessment Models (HyRAM) and computational fluid dynamics modeling to characterize these scenarios. The results of the risk analysis and modeling efforts will then be used to inform future fire code requirements for hydrogen fuel cell electric vehicles.

The Safety Codes and Standards program focuses on understanding, characterizing, and developing reduced order models for hydrogen behavior when it is released or leaks from a system. These capabilities directly feed into the risk analyses that we perform in order to provide scientific justification for code requirements that will enable the wider implementation of new and unique hydrogen applications. Additionally, our materials compatibility studies provide test methods to evaluate materials for hydrogen service. This program covers four topic areas: hydrogen behavior studies, risk analysis, materials compatibility, and regulatory code development and support for the Office of Energy Efficiency and Renewable Energy and Fuel Cell Technology.

Investments

Advanced materials testing research is conducted at the Center for Integrated Nanotechnologies (CINT) in support of oil and gas pipeline applications. CINT is a Department of Energy-funded nanoscience research facility that provides users from around the world with access to state-of-the-art expertise and instrumentation in a collaborative, multidisciplinary environment with a focus on nanoscience integration. CINT research has focused on developing means to understand the mechanical, thermal, and chemical effects influencing subsurface fluid flow over a range of length scales. This work further addresses such technical challenges as predicting the behavior of multiply coupled systems at multiple scales, determining in-situ subsurface stresses with high reliability, and optimizing the computational efficiency of simulations.

The Combustion Research Facility (CRF) is a Department of Energy Office of Science Collaborative Research Facility. The CRF focuses on engine, combustion, combustion kinetics, flame chemistry, engine analysis, reacting flows, alternative fuels/power, and hydrogen research. The facility hosts more than 100 visiting researchers every year from around the world. They include postdocs, university faculty and graduate students, high school teachers, industrial collaborators, and national laboratory and government researchers. Researchers work with industrial partners on both precompetitive projects that are shared with the community and on proprietary projects that are wholly owned by the sponsor.

Sandia has developed a low Mach fluids/radiation transport code that primarily supports the capability to simulate the abnormal-thermal environment (i.e., transient object heat-up in hydrocarbon pool fire environments that might arise during transportation or storage-accident scenarios) for hazard and safety assessments. The core capability of this simulation tool is laminar/turbulent fluid mechanics and a combination of thermal/isothermal and uniform/nonuniform (with reactions) transport. Fuego was developed under the object-oriented SIERRA Framework to easily facilitate multi-mechanics coupling in a robust, verified, software-quality assured analysis tool.

Future

Future work at Sandia includes a continuation of cutting-edge technology and research that expand on Sandia’s core capabilities and investments. The group will continue to focus on advanced materials and longer lifetimes. Additionally, research and development will focus on:

- Liners and coatings to prevent or slow corrosion.

- Embedded electrochemical and fiberoptic sensors within the pipeline liner or coating.

- Predictive modeling, machine learning, data analytics, and applied artificial intelligence with collected data.

Contact

Michael Starr

(505) 284-9614