Page • Blade Reliability and Composite Materials Improving wind-turbine blade manufacturing quality and determining the most cost-effective methods to mitigate environmental damage. Unplanned maintenance and component failures are a concern to both wind plant owners and wind turbine manufacturers. Sandia leads efforts in wind-turbine reliability research, specifically focusing on: Wind plant reliability...

Search

Blade Reliability Collaborative

Page • Blade Reliability Collaborative Reliability, Operations and Maintenance, and Standards Wind-turbine blades are among the largest composite structures made in the world. The economics of energy production dictates that low-cost manufacturing methods be employed to produce cost-effective machines. This, combined with an often harsh operating environment, creates a challenge for blade...

Boost your H2IQ: Newly available webinar provides overview of hydrogen internal combustion engine (H2ICE) technologies

News Article, March 23, 2023 • Sandia hydrogen expert Aleš Srna joined researchers from Argonne National Laboratory on February 22nd to present an overview of hydrogen internal combustion engine (H2ICE) technologies as part of the monthly H2IQ webinar series organized and hosted by the Department of Energy (DOE) Hydrogen and Fuel Cell Technologies Office. The February...

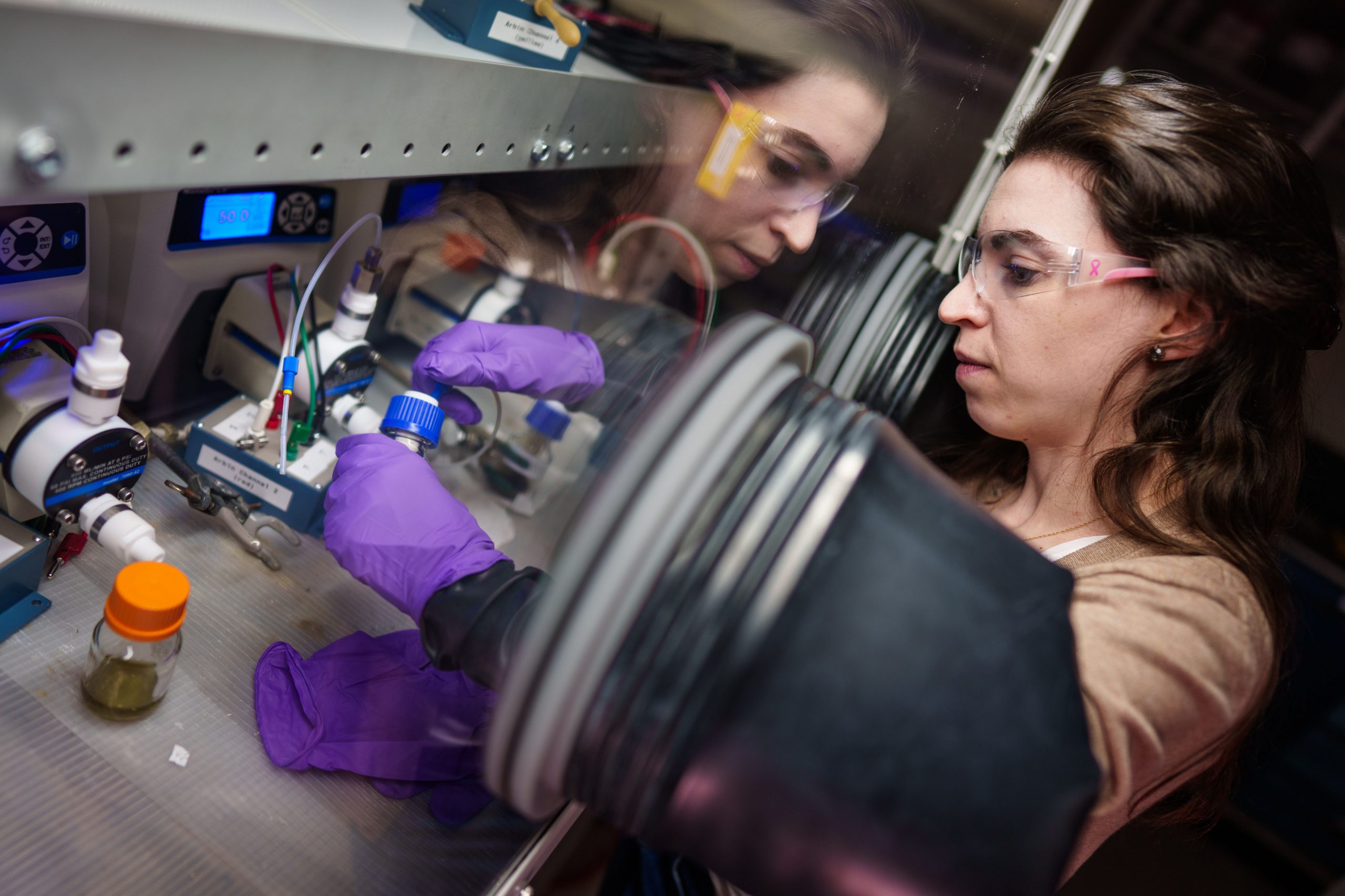

Boosting battery research

News Article, June 18, 2024 • Most Americans don’t leave home without at least one lithium battery-powered device, and someday, the house itself may have a battery back-up. Scientists at Sandia National Laboratories are working to make these large back-up batteries less expensive, hold more energy and be less prone to bursting into flame. One way...

Braden Smith

Staff Page • Optical Engineer. Biography Since 2021, Braden Smith has worked at Sandia National Laboratories’ National Solar Thermal Test Facility (NSTTF) as an optical engineer. Braden previously worked as an optical engineer specializing in remote sensing, working primarily with the simulation and calibration of remote sensing systems. Now, Braden’s research focuses on...

Brandon Davis

Staff Page • Testing and Operations Engineer. Biography Brandon Davis is a senior member of the engineering staff in Sandia National Laboratories’ Wind Energy Design and Experimentation Department. Since 2010 he has worked in renewable energy technologies and has a background in electrical power systems and control. Since joining the department, he has...

Brandon Ennis

Staff Page • Rotor Aeroelastic Lead. Biography Dr. Brandon Ennis joined Sandia National Laboratories in 2014 and is a member of the Wind Energy Computational Sciences Department. He has supported multiple projects performing rotor structural design as the aeroelastics lead for the National Rotor Testbed and offshore vertical-axis wind turbine projects, wind turbine...

Brantley Mills

Staff Page • R&D S&E, Mechanical Engineering. Biography In February 2015, Brantley joined Sandia National Laboratories as a senior member of the technical staff in the Thermal Sciences and Engineering Program. He has worked in a broad range of heat transfer and fluids subject areas including thermal systems analysis, thermal-fluid cryogenics, reduced-order modeling,...

Brayton Cycle Test Loop

Facility • Using the Nuclear Energy Systems Laboratory (NESL) / Brayton Lab, Sandia National Laboratories is creating a thermal-to-electric power conversion technology in a configuration called the recompression closed Brayton cycle (RCBC) that uses supercritical carbon dioxide (sCO2) as the working fluid, rather than steam, thereby dramatically increasing conversion efficiency compared to the...

Brent G. Austgen

Staff Page • Member of Technical Staff. Biography Brent G. Austgen is a Member of the Technical Staff in the Electric Power Systems Research Department at Sandia National Laboratories. He attained his Ph.D. degree (2024) and M.S. degree (2019) in operations research at The University of Texas at Austin and his B.S. degree...

Results 81–90 of 625