Materials science, experts, and facilities to support and strengthen the manufacturing sector.

Sandia’s advanced manufacturing program applies our manufacturing expertise and capabilities for energy technology manufacturing. Our foundational and applied R&D can solve a variety of emerging national problems facing the manufacturing sector.

After more than seventy years of delivering essential science and technology for national security, Sandia has established, varied manufacturing capabilities. For example:

- Sandia maintains silicon and compound semiconductor fabrication capabilities for low-volume, trusted, specialty research, development, and production.

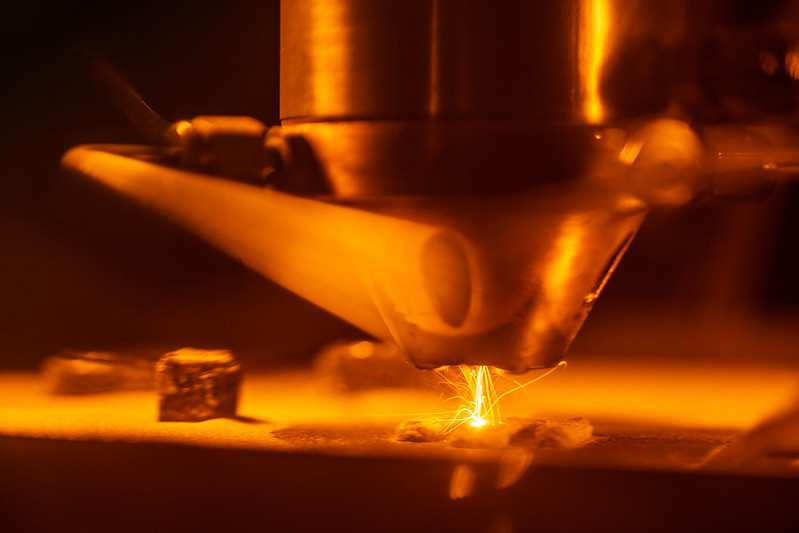

- Sandia develops or maintains various non-semiconductor additive and advanced manufacturing process capabilities for metals, ceramics, polymer, and other materials and components. For instance, LENS® — Laser Engineered Net ShapingTM — was developed at Sandia. LENS uses computer-controlled lasers that, in hours, weld air-blown streams of metallic powders into custom parts and manufacturing molds.

- Sandia advances digital engineering and manufacturing, qualification strategies, and cybersecure manufacturing approaches.

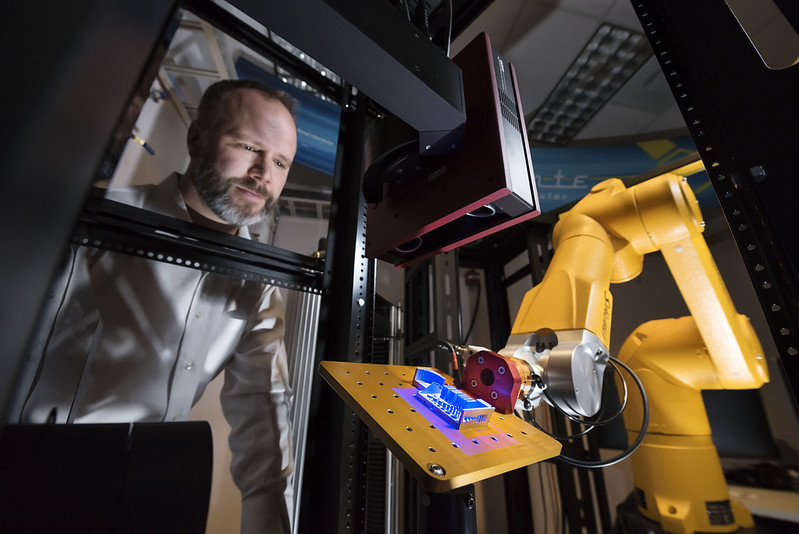

We continuously evolve our advanced manufacturing capabilities and activities. This includes researching, developing, and enabling next-generation processing approaches, agile supply chains, test and inspection methodologies, artificial intelligence and machine learning implementation in manufacturing, digital manufacturing and digital twin development, and component qualification. Sandia also has significant biological science facilities and expertise, including in biomanufacturing.

Areas of Focus

Advanced Micro- and Power Electronics

Sandia performs strategic, coordinated research and development to advance the energy efficiency and performance of next-generation microelectronics, often in partnership with others.

Our work increases the capability and availability of next-generation power electronics and related passive components (i.e., advanced soft magnets) to enable next-generation manufacturing, transportation, and power grid infrastructure.

Advanced Materials and Manufacturing Processes

Sandia partners to develop innovative materials and efficient manufacturing processes. Our relevant capabilities include advanced manufacturing processing, electrical connectors, high entropy alloys, composites and feedstocks, AI/ML-enabled manufacturing approaches, and cybersecure manufacturing.

Select R&D Capabilities

- Novel materials synthesis and discovery for at-risk material replacement and application-specific material development

- AI/ML techniques for accelerated materials discovery and advanced manufacturing efficiency

- Advanced feedstock materials development for performance, cost, and supply chain requirements

- High entropy alloys for both refractory and lightweighting purposes

- Composites for thermal protection and other applications

- LENS and various polymer processing (e.g., direct ink writing) research and development

- AI and advanced manufacturing capabilities for rapid prototyping: designers and production engineers work together to rapidly manufacture development builds that satisfy both design and production requirements

- Mature, qualified materials and manufacturing processes that meet requirements for energy and nuclear security missions

- Accelerated qualification of additively manufactured components

- Cybersecurity for supply chain management: Engineers and specialists from Sandia lend their expertise to the Cybersecurity Manufacturing Innovation Institute (CyManII), a national research institute leveraging the strengths of DOE’s national laboratories to secure U.S. manufacturing. CyManII is funded by the Department of Energy’s Advanced Materials and Manufacturing Technologies Office.

- Facilities for characterization, synthesis, device integration, fabrication, testing, and validation such as the Microsystems Engineering, Science and Applications and Center for Integrated Nanotechnologies

- Special capabilities for wide and ultrawide band gap devices using vertical AlGaN components for increased voltage breakdown, power handling, and operation in extreme environments

- Advanced synthesis, characterization, testing and heterogeneous characterization

- Advanced power electronics (GaN, SiC, etc.) reliability science and packaging

- Specialty, high reliability connectors and direct-ink-write printed electronics

Contact

Carlos Gutierrez, Program Manager

Grace McNealy, Business Development & Partnerships