Hydrogen Extremely Low Probability of Rupture (HELPR) is a modular, probabilistic fracture mechanics platform developed to assess the structural integrity of natural gas infrastructure for transmission and distribution of hydrogen natural gas blends. HELPR contains fatigue and fracture engineering models to allow fast computations while its probabilistic framework enables users to explore and characterize the sensitivity of predicted outcomes to uncertainties within the pipeline’s structure and operation.

HELPR development was supported by the Office of Energy Efficiency and Renewable Energy’s (EERE) Hydrogen and Fuel Cell Technologies Office (HFTO) within the U.S. Department of Energy (DOE).

The HELPR software is available under the open-source 3-Clause BSD License.

Overview

HELPR includes the following features:

- Applicable to pressurized cylindrical shells

- Fast running, deterministic engineering models

- Fatigue life estimation

- ASME B31.12 Code Case 220 fatigue design curves with pressure and stress ratio dependence

- Track crack growth over time, assuming cyclic pressure loading

- Stress intensity factor calculations for both internal and external (longitudinal) flaws based on solutions from API 579-1/ASME FFS-1

- Anderson Textbook 2nd Edition and API 579-1 solutions available

- Failure assessment diagrams

- Probabilistic framework to provide predictions with uncertainty estimates

- Support for both characterized variability and unknown uncertainties

- Sensitivity studies to understand impact of input parameters on predicted quantities of interest

Given a user-defined system, HELPR can be used to:

- Estimate remaining fatigue life for a set of operating conditions

- Explore the impact of transporting different volume fractions of hydrogen on a pipeline’s temporal structural integrity

- Determine which operational parameter variabilities have the most significant impact on a pipeline’s structural integrity

Documentation

- Suggested citation for HELPR v2.0.0: Benjamin B. Schroeder, Cianan Sims, Benjamin R. Liu, Michael C. Devin, and Bailey Lucero. HELPR (Hydrogen Extremely Low Probability of Rupture), Version 2.0.0. Sandia National Laboratories (December 9, 2024); software available at: https://helpr.sandia.gov.

- B. Schroeder, R. Dingreville, C. San Marchi, and J. Ronevich: “Probabilistic Fracture Mechanics Toolkit for Hydrogen Blends in Natural Gas Infrastructure”. International Hydrogen Conference, Park City, UT, 17-20 September 2023, SAND2023-08941C.

- B. Schroeder, C. San Marchi, R. Dingreville, J. Ronevich: “Probabilistic Fracture Mechanics Toolkit for Hydrogen Blends in Natural Gas Infrastructure”, Emerging Fuels Symposium, 5-8 June 2023, Orlando FL, SAND2023-3992C.

- B. Schroeder, C. San Marchi, J. Ronevich, M. Devin, J. Duell, and S. Potts: “Utilizing Probabilistic Analyses to Explore Performance Margins of Natural Gas Infrastructure for the Transport and Delivery of Hydrogen and Hydrogen Blends”, ASME Pressure Vessels & Piping Conference, July 29 – August 01 2024, Bellevue WA, SAND2024-09668C (Presentation), SAND2024-04359C (Proceedings Paper PVP2024-125226).

- B. Schroeder: “An Overview of the Hydrogen Extremely Low Probability of Rupture (HELPR) Toolkit for Probabilistic Structural Integrity Assessments When Transporting Hydrogen in Natural Gas Infrastructure”, Presentation for EPRI/Sandia Expert Workshop on Challenges and Solutions to Implementation and Reliable Operation of Large-Scale Gaseous Hydrogen Infrastructure at the ASME Pressure Vessels & Piping Conference, August 01 2024, Bellevue WA, SAND2024-09667C.

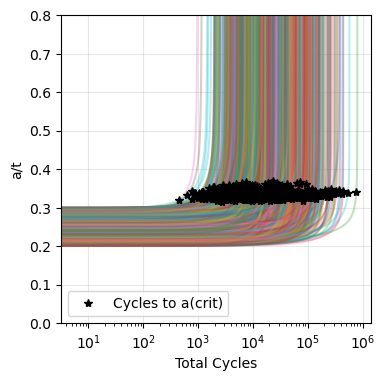

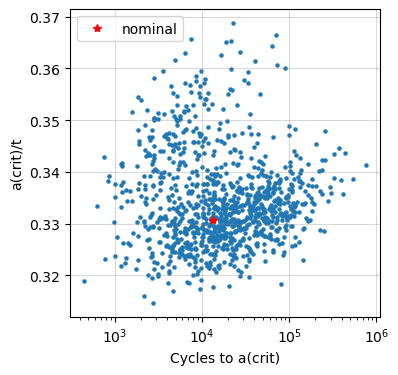

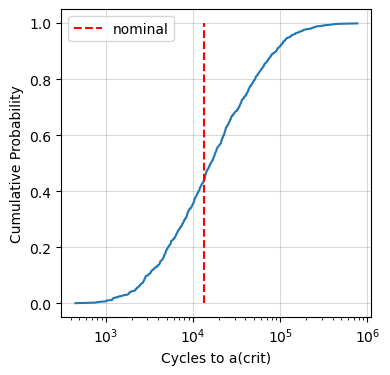

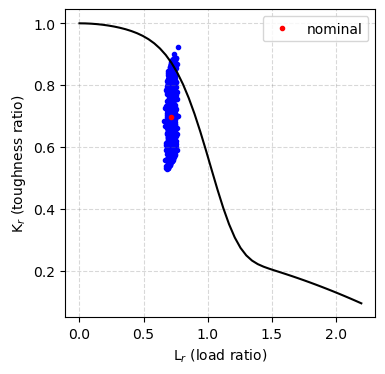

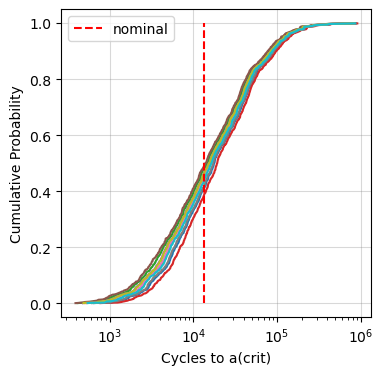

Sample Outputs

See examples of data below that were produced using HELPR.

© 2024 National Technology & Engineering Solutions of Sandia, LLC (NTESS). Under the terms of Contract DE-NA0003525 with NTESS, the U.S. Government retains rights in this software.

Contact

Benjamin Schroeder

HELPR Team Lead

bbschro@sandia.gov

Chris San Marchi

Hydrogen Materials Expert

cwsanma@sandia.gov

Joe Ronevich

Hydrogen Materials Expert

jaronev@sandia.gov