Hydrogen Fuel Cell Project at Honolulu Harbor

Hydrogen fuel cells have a long track record of supplying efficient, clean power for a wide range of applications, including forklifts, emergency backup systems, and vehicles. An analysis by Sandia and the Department of Energy showed that due to fluctuating loads in maritime auxiliary power applications, a hydrogen fuel cell, which follows the load, is more energy efficient than a diesel engine. A hydrogen fuel cell only supplies power when it is needed. The Maritime Hydrogen Fuel Cell Project demonstrated this analysis in a commercial port setting.

The project began its field trials in August 2015 with a six-month deployment hosted by Young Brothers Ltd., a subsidiary of Foss Maritime Co., at its facility in the Honolulu Harbor. The U.S. Department of Energy’s Hydrogen and Fuel Cell Technologies Office and the U.S. Department of Transportation’s Maritime Administration co-funded the pilot. The pilot hydrogen fuel cell unit replaced a diesel generator used to provide power for refrigerated containers on land and on transport barges.

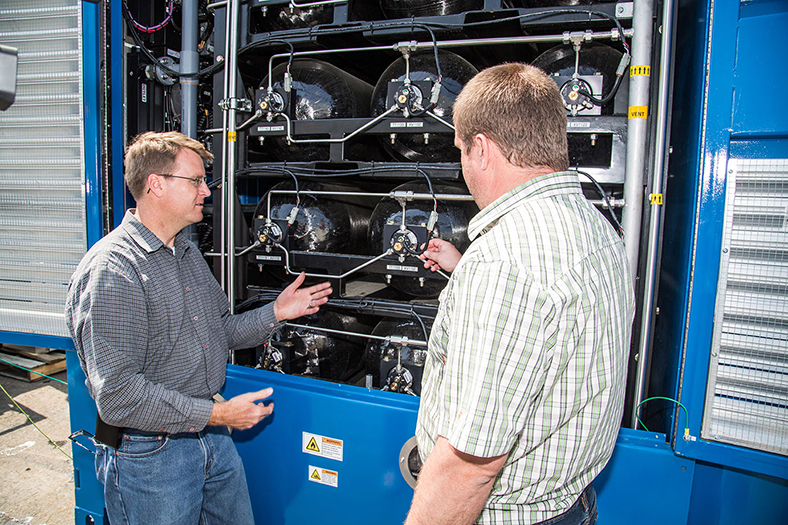

Hydrogenics Corp. designed and manufactured a containerized 100-kilowatt hydrogen fuel cell unit, which included the fuel cell engine, a hydrogen storage system, and power-conversion equipment. Built into a standard shipping container, the unit’s outward appearance and functionality was similar to maritime diesel generators in use at the time.

As the primary interisland shipper of goods within Hawaii, Young Brothers Ltd. had a strong environmental and financial interest in the project. After initially using the hydrogen fuel cell unit on land, Young Brothers Ltd. planned to deploy the unit to power refrigerated containers onboard barges traveling between the Honolulu and Kahului harbors.

During the six-month deployment, performance feedback and data were collected to determine the environmental, energy, and cost savings from the hydrogen fuel cell unit. Sandia analyzed the operational, safety, and cost performance data to develop a business case for using hydrogen fuel cells at other commercial ports. In addition, the safety aspects and feedback from the unit’s design and operation may guide regulators toward formal codes and standards for hydrogen and fuel cells in maritime applications, thereby increasing the likelihood of this clean-energy technology being adopted for maritime use.

Major commercial ports can produce daily emissions equal to those of half a million cars or more. To combat these environmental impacts, many U.S. ports have begun to adopt green practices. Hydrogen fuel cells have the potential to meet the electrical demands of vessels in ports, as well as supply power for other port uses, such as yard trucks, forklifts, and other materials-handling specialty equipment. If implemented, hydrogen fuel cells, which produce zero pollutant emissions and no greenhouse gases at the point of use, can reduce the overall amount of diesel or other maritime fuel used.

Project Partners

In addition to serving as the overall project leader and coordinator for the 12-partner team, Sandia provided unique expertise in hydrogen materials, systems, risk analysis, and codes and standards development. Sandia was also responsible for hydrogen supply and delivery coordination and will conduct independent technical and business-case analyses. As the primary project partners, Sandia, Young Brothers Ltd., and Hydrogenics Corp. all contributed significant time and/or equipment to the Maritime Fuel Cell Project at their own cost.

Resources

- Video

- Final Report

- Safety Features Integrated into Design and Use of System

- Maritime Application of Hydrogen Fuel Cell Demonstration Project at Young Brothers, Limited

- Press Release: Nothing but water

Contact

Leonard Klebanoff

(925) 294-3471

lekleba@sandia.gov