Making marine energy a feasible addition to the United States’ energy portfolio is about more than building tidal turbines or wave energy convertors (WECs). It’s also about the unseen tethers that keep these systems operating far from shore. Beneath the waves, mooring lines hold marine energy devices in place, and umbilical cables deliver power and data to shore. These components face some of the harshest conditions on Earth, and their failure can cause costly downtime, environmental hazards, or even the loss of an entire system.

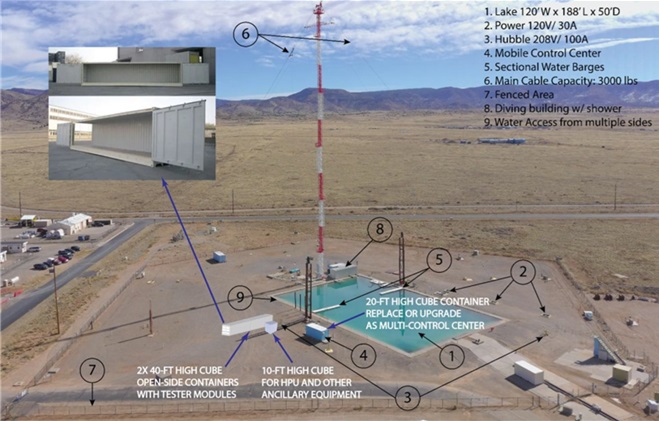

That’s where Sandia National Laboratories’ new Line Inspection and Guided Hardware Testing (LIGHT) Lab comes in. Located in Albuquerque, New Mexico, the LIGHT facility is designed to test and validate the performance of marine energy umbilicals, mooring lines, and belts before they ever see the open ocean. While still in development, the facility is scheduled to open in 2027 with the goal of making marine deployments safer, more reliable, and less risky.

Testing marine energy systems on land

Marine energy systems are expensive to install and maintain. Sending an unproven mooring line or umbilical into the water can lead to premature failures that are difficult and costly to fix. The LIGHT Lab will provide a controlled environment to simulate real-world stress such as the tension, bending, and twisting that underwater lines and umbilical cables endure. This allows engineers to pinpoint weak spots, understand system capabilities, and verify that components meet strict performance standards.

Specialized testing modules

The LIGHT Lab’s capabilities are built around three purpose-designed modules:

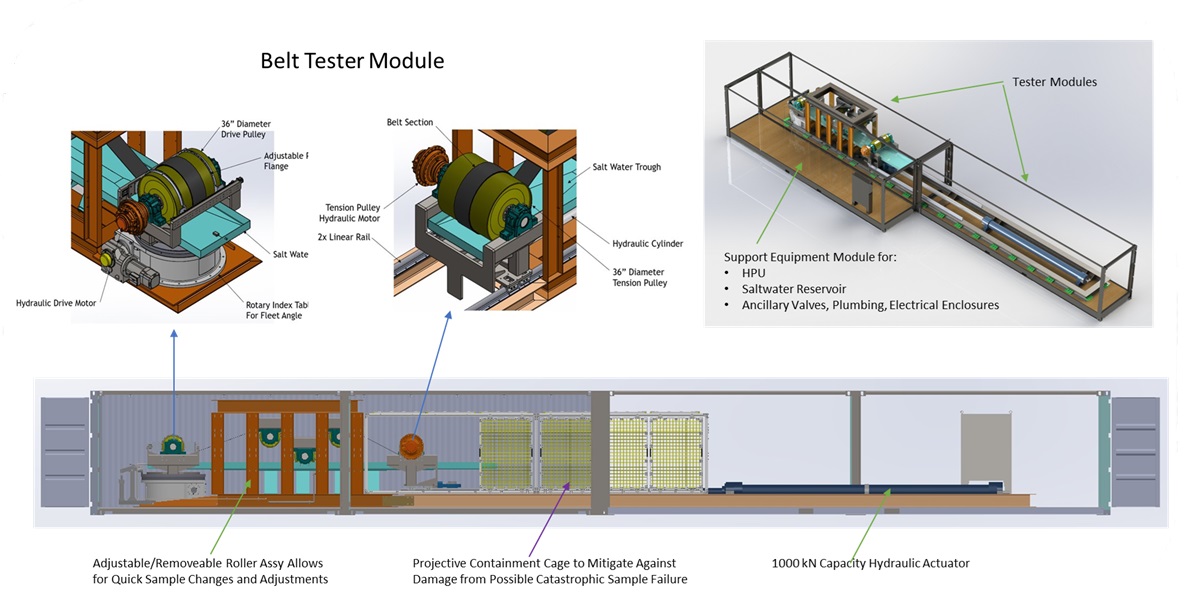

- Belt Tester Module (BTM): The BTM evaluates mooring belts that serve as part of the power take off system for WECs. One of the belt ends is typically anchored at the ocean bottom or a semi static component below the WEC, while the other end connects to a rotary power take-off pulley or drum. The BTM is designed to simulate the millions of wrap-unwrap cycles the belt will experience around the pulleys and drum in an ocean deployment, helping engineers understand how materials perform under cyclic operation. The BTM can accommodate multiple drums with various sizes up to one meter in diameter.

- Mooring Line Tester Module (MLTM): The MLTM can apply up to 1000 kilonewton tension on articles for a breaking test, as well as cyclical- and torsion-loading, simulating the forces caused by waves, tides, and currents.

- Umbilical Tester Module (UTM): This module is tailored to the unique challenges of umbilical cables, which can elongate by more than twice their original length. These cables often carry both electrical power and data through electrical and fiber-optic cables. The UTM can apply bending, tension, and torsion and is equipped with a 6-meter stroke piston for elongation testing.

Collaboration with a growing industry

The LIGHT Lab is being developed in consultation with marine energy developers, equipment manufacturers, and other research organizations. By creating a shared testing resource, Sandia aims to accelerate innovation in the industry and support the deployment of durable, dependable marine energy systems.

Looking ahead

As energy generation expands into the oceans and other offshore environments, facilities like LIGHT will be essential for ensuring device reliability. By testing cables and lines to their limits on land, engineers can send them into the ocean with confidence. In the long run, that means fewer failures, lower maintenance costs, and a smoother path toward strengthening America’s energy systems and marine energy economy.

September 16, 2025