Blade Reliability and Composite Materials

Improving wind-turbine blade manufacturing quality and determining the most cost-effective methods to mitigate environmental damage.

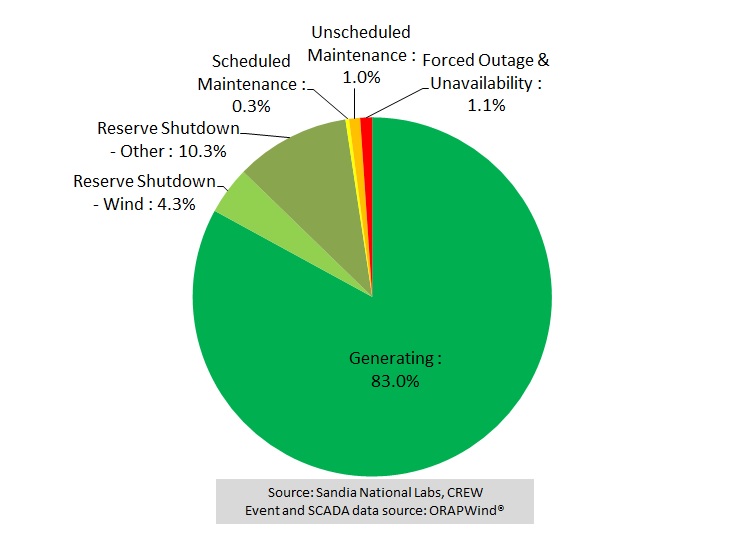

Unplanned maintenance and component failures are a concern to both wind plant owners and wind turbine manufacturers. Sandia leads efforts in wind-turbine reliability research, specifically focusing on:

- Wind plant reliability and analysis

- Nondestructive inspection

- Composite materials research

- Optimized carbon fiber composites

- Structural health monitoring

- Effects of blade defects

- Leading edge erosion

Through this work, Sandia ensures that wind energy technology will deliver economical and reliable energy to the nation.

Research Focus Areas

Sandia works with industry partners to collect and analyze wind turbine reliability data in order to improve the predictability and reliability of wind power generation and operations. Researchers are analyzing proprietary data from industry partners to provide generalized characterizations of wind plant reliability issues and opportunities for improvement. When complete, these databases will allow industry to self-assess their turbines’ performance and make more informed operations decisions that improve power generation.

Sandia National Laboratories’ Infrastructure Assurance and Non-Destructive Inspection Department began as part of the Federal Aviation Administration’s program to improve the airworthiness of the U.S. commercial aviation fleet, and transition from safe-life to damage-tolerant design. This transition required the development of improved design, inspection, and repair processes, that have since been applied to military aircraft, spacecraft, bridges, automobiles, trains, oil and gas industry equipment, and now wind blades.

The Wind Blade Non-Destructive Inspection Center now includes wind blade inspection specimens and inspection technology specifically suited to wind blades. Real and engineered specimens include all flaws and damage types that are commonly found in wind blades in both manufacturing floor and field settings.

The Wind Blade Non-Destructive Inspection Center provides the following capabilities and expertise:

- Nondestructive inspection

- Automated and robotic inspection deployment

- Structural health monitoring and sensor development

- Composite fabrication and structural repair

- Structural mechanics and damage tolerance analysis

- Fatigue, fracture and strength mechanical testing

- Reliability and probabilistic analysis

Longer blades present new technical and economic challenges that cannot be addressed without a thorough understanding of composite material behavior in realistic wind applications. Since 1989, Sandia and its partners at Montana State University have tested and reported key data and trends on fiber-reinforced polymers, or composites, and other materials used in the construction of wind turbine blades. Developers and researchers can access the results of more than 1600 tests on more than 500 materials in the DOE/SNL/MSU Wind and Marine Energy Composites Database.

Sandia’s composites research capabilities include:

- Testing the effects of common flaws in composites on properties in fatigue loading

- Characterizing new materials such as urethane resins, aligned strand material forms, and carbon fiber composites

- Studying crack growth and delamination in adhesive and core materials

- Establishing full 3-D properties of thick laminates

- Developing substructure testing capabilities in order to capture the realistic and complex loading experienced by modern wind-turbine blades.

- Incorporating new test diagnostics such as Acoustic Emission Spectroscopy to improve understanding of in-situ material behavior

Carbon fiber reinforced polymers, or carbon fiber composites, offer significantly enhanced mechanical properties compared to the more widely used glass fiber reinforced polymers, enabling the design and manufacture of larger, high energy capture wind turbine rotors. However, commercial carbon fiber materials are much costlier than glass fiber, hindering their broader adoption in the wind industry. Carbon fiber composites were originally designed and applied to military and aerospace applications where strength is paramount and cost was not a primary factor. Thus, significant opportunities exist to reduce the overall cost of incorporating carbon fiber materials into a wind turbine blade where cost is a primary factor. These opportunities range from changing the raw material inputs, fiber conversion processes, and formats of the carbon fiber itself, through the composite material forms, e.g. pultrusion, or prepreg, used in the blade manufacturing process.

The magnitude of the wind-specific value improvement of novel carbon fiber materials is determined through characterization of carbon fiber material properties by performing mechanical testing and accurate cost modeling. The performance of study carbon fiber materials is assessed through blade system optimization studies for representative wind turbine reference models.

Sandia and its partners have performed research on novel carbon fiber materials to assess the commercial viability to develop cost-competitive carbon fiber composites specifically suited for the unique loading experienced by wind turbine blades. This work enables the continued reduction in the levelized cost of energy (LCOE) for wind turbines installed in the United States, including low wind resource and offshore sites, and has established routes for the broader adoption of carbon fiber materials in wind turbine blade design beyond existing commercial materials.

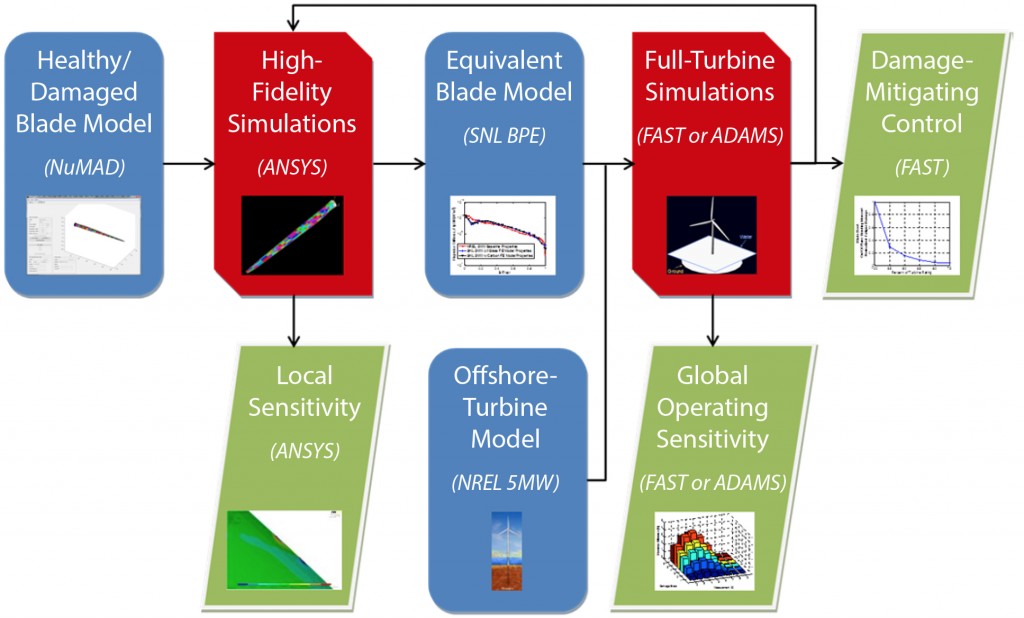

Sandia develops reliable strategies to detect damage in the rotor blades early enough to allow operators to make operations, maintenance, and repair decisions that will reduce costs. Researchers developed a Structural Health and Performance Management System, a cost-effective, simulation-based approach for preventing, detecting, and addressing damage. This method bridges the gap between detecting damage in a wind turbine blade and making revenue-optimizing operations and management decisions based on the effects of the damage.

Defects in wind turbine blades can have wide range of effects depending on their location, material, type, and size. Because existing inspection procedures from other industries often miss defects, manufacturers overdesign blades to account for possible defects.

Sandia researchers use nondestructive inspection techniques on flawed blade specimens to characterize flaws and determine the ultimate effects of undetected defects.

Leading edge erosion is an emerging issue in wind turbine blade reliability, causing performance decreases and additional maintenance costs. Through the U.S. Department of Energy’s Blade Reliability Collaborative, researchers from Sandia National Laboratories, Texas A&M, and U.C. Davis have recently addressed the subject of performance loss. This project includes roughness measurements at wind plants experiencing blade soiling and erosion, wind tunnel testing of airfoils with representative roughness and erosion levels, and the development of a model that captures the performance effects of blade surface roughness and erosion.

More information on this work, including several reports and a data archive, are available on the Leading Edge Erosion webpage.

Work with Us

We partner with large and small businesses, universities, and government agencies. With multiple agreement types to select from, partners can access world-class science, engineering, experts, and infrastructure.

Contact

Brandon Ennis

blennis@sandia.gov

David Maniaci

dcmania@sandia.gov