Safety standards for maintenance facilities of liquid and compressed gas fueled large-scale vehicles ensures proper facility design and operations. Sandia provides technical assistance to the Department of Energy, Clean Cities coordinators, Clean Cities stakeholders, and advanced technology end-users to investigate natural gas vehicle (NGV) leak scenarios inside maintenance facilities.

Our work in this area focuses on:

- Developing reduced-order engineering models of compressed natural gas/liquid natural gas/propane release behavior.

- Evaluating key risk scenarios to develop best practices and code revisions.

- Developing educational materials and informing code committees of risk mitigation strategies.

The goals of this work are to create a robust modeling capability that can simulate current and future alternative fuels, develop and communicate educational material for target audiences, and inform codes and standards with scientifically based results.

Publications

Analyses in Support of Risk-Informed Natural Gas Vehicle Maintenance Facility Codes and Standards: Phase II, by Myra L. Blaylock, Chris LaFleur, Alice B. Muna, Brian D. Ehrhart, Sandia National Laboratories, March 2018. SAND2018-2945.

Analyses in Support of Risk-Informed Natural Gas Vehicle Maintenance Facility Codes and Standards: Phase I, by Isaac W. Ekoto, Myra L. Blaylock, Christine A. LaFleur, Jeffery L. LaChance, Douglas B. Horne, Sandia National Laboratories, March 2014. SAND2014-2342.

Analysis of a Full Scale Blowdown Due to a Mechanical Failure of a Pressure Relief Device in a Natural Gas Vehicle Maintenance Facility by Myra Blaylock, Radoslav Bozinoski, and Isaac Ekoto. Sandia National Laboratories, May 2016. SAND2016-4534.

Presentation at the NGV Technology Forum, October 18 and 19, 2016, in San Diego, California, by Myra Blaylock Sandia National Laboratories, 2016. SAND2016-10561 PE.

Presentation at the NGV America Technology Committee Maintenance Facility Working Group, by Myra Blaylock, Sandia National Laboratories, 2016. SAND2016-5842 PE.

Risk-Informed LNG/CNG Maintenance Facility Codes and Standards, by Chris LaFleur, Myra Blaylock, Rad Bozinoski, Amanda Dodd, Ethan Hecht, Doug Horne, Alice Muña, Sandia National Laboratories, 2015. SAND2015-7361PE.

Guideline for Determining the Modifications Required for Adding Compressed Natural Gas and Liquefied Natural Gas Vehicles to Existing Maintenance Facilities, by Dan Bowerson, NGVAmerica Technology & Development Committee, 2017.

Natural Gas Vehicles for America

Videos

Maintenance Garage Description

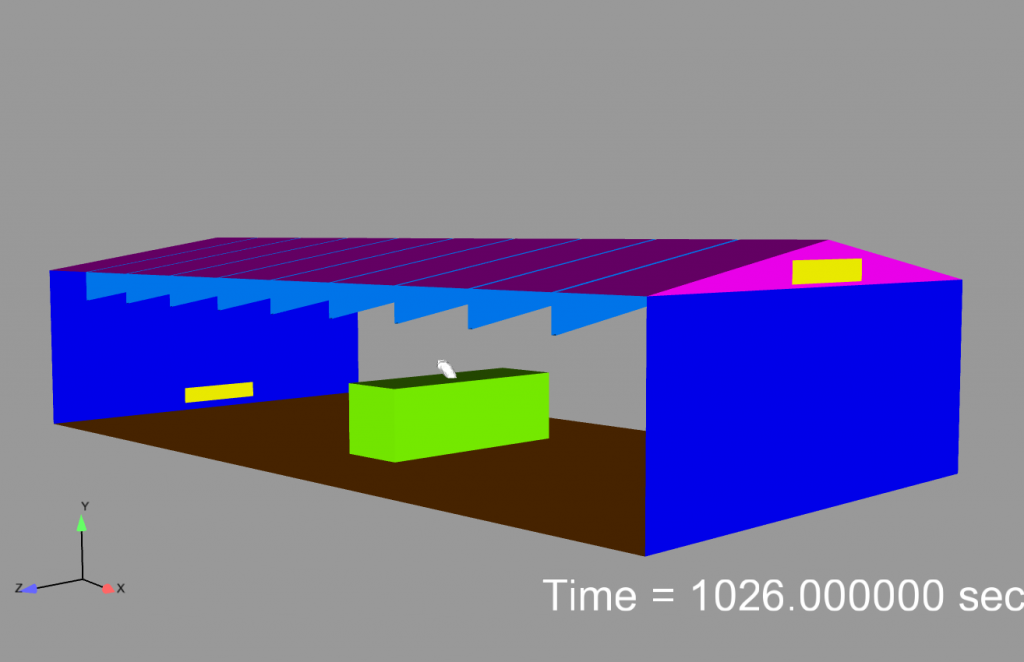

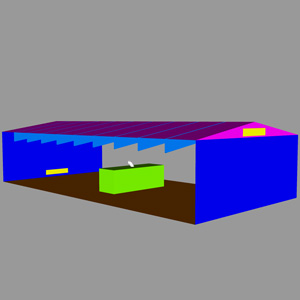

Single volume building enclosure modeled:

- 30.5 m long (100’)

- 15.2 m wide (50’)

- 6.1 m tall (20’)

- 1:6 pitched roof

Option for horizontal support beams:

- investigate accumulation of flammable mixture in discrete pockets

- nine beams

Two air circulation vents:

- one near the floor on a short building side-wall

- second on the opposite side wall near the roof

Natural Gas Vehicle (NGV) modeled as a cuboid:

- 2.44 m (8’) tall and wide

- 7.31 m (24’) long

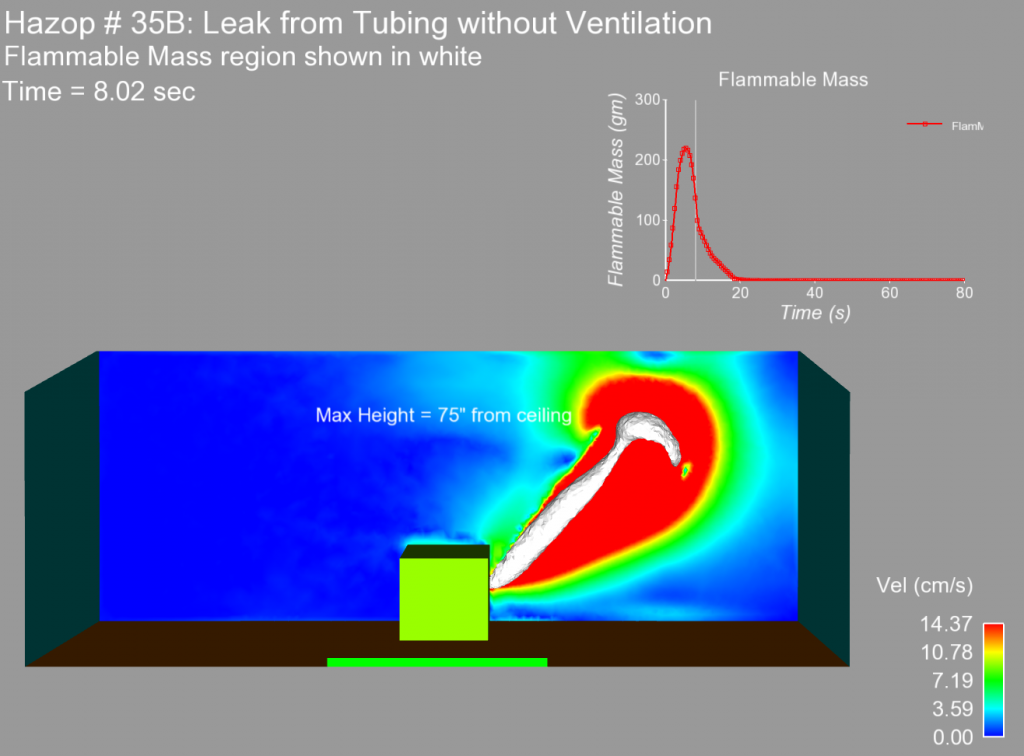

CNG and LNG Fuel System Line Cracking

Described in SAND2014-2342.

Tubing leak flow (cracking open tubing joint)

Scenario Basis:

A natural gas release may occur during the purge of a vehicle fuel system as part of regular operational maintenance on a Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG) fueled vehicle.

Prior to starting maintenance, a technician purges the remaining natural gas by cracking a ½” tube fitting on the fuel system, on the vehicle side, at a height of 1.0 meter from the floor.

CNG Scenario Criteria:

This video is of a CNG line cracking where the storage volume is 3.3 liters (201 in3) and the storage pressure is 248 bar (3600 psia), which is an overall natural gas fuel system mass of 630 g.

Transient blowdowns were modeled as an isentropic expansion using NETFLOW (SAND2001-8422).

Mechanical Failure of a Thermally Activated PRD (worst case scenario, not necessarily credible)

Described in SAND2016-4534.

Full storage tank blowdown

Scenario Basis:

In the event a Compressed Natural Gas (CNG) vehicle cylinder becomes engulfed in a flame, onboard storage cylinders are protected against excessive pressure buildup by a thermally triggered Pressure Relief Device (PRD) designed to fully open without the possibility for reseat in the event of activation.

Inadvertent actuation due to a mechanical failure would result in a rapid and uncontrollable decompression of all cylinder contents.

Advances such as the use of dual activated valves have been implemented to reduce the likelihood of unintended release, although there remains some nominal risk due to the potential for human error.

The Standards Development Organizations view such a release as a bounding event for hazard potential.

Scenario Criteria:

For this scenario, the entire contents of a 700 L (42,700 in3), fully pressurized (250 bar) (3600 psia) CNG cylinder at room temperature (294 K) was released into the NGV maintenance facility.

NETFLOW was used to model the transient blowdown.

Contact

Chris LaFleur

aclafle@sandia.gov