Concentrating Solar Thermal Technologies

Developing and testing concentrating solar thermal technologies for over 40 years

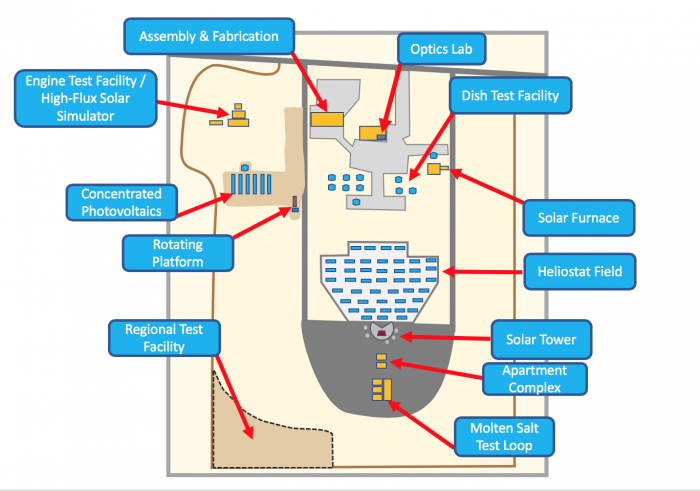

The National Solar Thermal Test Facility is the only test facility of its kind in the United States, providing a range of high flux and extreme temperature capabilities using concentrated sunlight to support the development of renewable energy technologies and the next generation of materials.

Research Focus Areas

Tools

Solar Glare Analysis Tool (SGHAT)

Availability

Due to new cybersecurity restrictions at Sandia, SGHAT is now available for internal Sandia use only. All external use of SGHAT is restricted, even by other government or military users. The glare tool source code and algorithms are available for licensing from Sandia Laboratories. Interested parties can contact the licensing department.

The licensed SGHAT applications are available for public use: ForgeSolar glare analysis tools at www.forgesolar.com If you have licensed SGHAT and would like to be listed, please contact us.

Solar Glare Hazard Analysis Tool

This tool determines when and where solar glare can occur throughout the year from a user-specified PV array as viewed from user-prescribed observation points. The potential ocular impact from the observed glare is also determined, along with a prediction of the annual energy production. Configurations can be quickly modified (e.g., tilt, orientation, shape, location) to identify a design that mitigates glare while maximizing energy production.

Meets FAA glare analysis requirements (78 FR 63276). SGHAT requires a modern web browser

Tower Illuminance Model

The Tower Illuminance Model is a real-time interactive concentrating solar field simulation. TIM models a concentrating tower receiver, heliostat field and potential reflected glare, based on user-specified parameters such as field capacity, tower height and location. TIM provides a navigable 3D interface, allowing the user to “fly” around the field to determine the potential glare hazard from off-target heliostats. Various heliostat aiming strategies are available to specify how heliostats behave when in standby mode. Strategies include annulus, point-per-group, up-aiming and single-point-focus. Additionally, TIM includes an avian path feature for approximating the irradiance and feather temperature of a bird flying through the field airspace.

Empirical Glare Analysis Tool

This tool allows the user to empirically quantify glint and glare from reflected light and assess the potential impact (e.g. temporary after-image, retinal burn). No expensive equipment is required. Users simply upload photos of the glare and the sun.

Analytical Glare Estimation Tool

Analytically predict the potential impact (e.g. temporary after-image, retinal burn) of observed glare.

Phlux Mapping Analysis Tool

This tool allows the user to empirically determine the irradiance distribution on a central receiver. No flux gauge is needed. Simply upload photos and fill in the details, and the tool does the rest.

Reflectivity Calculator Tool

This tool allows the user to calculate the reflectivity of a receiver using only raw photos and details such as location and heliostat characteristics.

Infrared Signature Analysis Tool (IRSAT)

The software tool Infrared Signature Analysis Tool was developed to enable users to evaluate the spectral irradiance from alternative systems at user-prescribed source temperatures and distances between the observer and source. The spectral irradiance profiles can then be analyzed for compatibility with optical sensors. In addition, computational fluid dynamics models have been developed to characterize vapor plumes generated from geothermal power plants.

Sandia Fringe Optical Analysis Slope Tool (SOFAST)

The Sandia Fringe Optical Analysis Slope Tool, or SOFAST, is used to characterize the surface slope of reflective mirrors for solar applications. SOFAST uses a large monitor or projections screen to display fringe patterns, and a machine vision camera to image the reflection of these patterns in the subject mirror. From these images, a detailed map of surface normals can be generated and compared to design or fitted mirror shapes. SOFAST uses standard Fringe Reflection, or deflectometry approaches, to measure the mirror surface normals. SOFAST uses an extrinsic analysis of key points on the facet to locate the camera and monitor relative to the facet coordinate system. It then refines this position based on the measured surface slope and integrated shape of the mirror facet. The facet is placed into a reference frame so that key points on the facet match the design facet in orientation and position. This is key to evaluating a facet as suitable for a specific solar application. SOFAST reports the measurements of the facet as detailed surface normal location in a format suitable for ray tracing optical analysis codes. SOFAST also reports summary information as to the facet fitted shape (monomial) and error parameters. Useful plots of the error distribution are also presented.

Alignment Implementation for Manufacturing Using Fringe Analysis Slope Technique (AIMFAST)

The proper alignment of facets on a dish engine concentrated solar power system is critical to the performance of the system. These systems are generally highly concentrating to produce high temperatures for maximum thermal efficiency so there is little tolerance for poor optical alignment. Improper alignment can lead to poor performance and shortened life through excessively high flux on the receiver surfaces, imbalanced power on multi-cylinder engines, and intercept losses at the aperture. Alignment approaches used in the past are time-consuming field operations, typically taking 4-6 hours per dish with 40-80 facets on the dish. Production systems of faceted dishes will need rapid, accurate alignment implemented in a fraction of an hour. AIMFAST presents an extension to our Sandia Optical Fringe Analysis Slope Technique mirror characterization system that will automatically acquire data, implement an alignment strategy, and provide real-time mirror angle corrections to actuators or labor beneath the dish. AIMFAST has been implemented and tested at the prototype level. AIMFAST has been used to rapidly characterize the dish system and provide near-real-time adjustment updates for each facet. The implemented approach can provide adjustment updates every 5 seconds, suitable for manual or automated adjustment of facets on a dish assembly line.

Universal Field Assessment, Correction and Enhancement Tool (UFACET)

UFACET is in development and funded by the U.S. Department of Energy’s Solar Energy Technologies Office. UFACET will use unmanned aerial systems and an imaging system payload to monitor optical errors in the heliostats while the heliostats are in operation or offline. UFACET can also be used to provide feedback during heliostat facet canting corrections.

Contact: Randy Brost

DelSOL

DelSOL is a performance and design code that includes optical and economic analyses. An analytical Hermite polynomial expansion/convolution-of-moments method is used to predict flux images from the heliostats in a computationally efficient manner, typically much faster than either MIRVAL or HELIOS. The code accounts for variations in insolation, cosine forshortening, shadowing and blocking, and spillage, along with atmospheric attenuation, mirror and receiver reflectivity, receiver radiation and convection, and piping losses. The code can be used to evaluate the system levelized energy cost and optimize the field layout, receiver dimensions, and tower height based on these costs. The code is written in FORTRAN77, and input to the code is entered via user-specified text files.

DELSOL3 source code, executable, and sample files

SOLERGY

SOLERGY simulates the operation and annual power output of a solar thermal power plant. It utilizes actual or simulated weather data at time intervals as short as three minutes and calculates the net electrical energy output including parasitic power requirements over a 24-hour day. Factors include energy losses in each component of the system, delays incurred during start-up, weather conditions, storage strategies, and power limitations for each component. The original version of SOLERGY (Stoddard et al., 1987) required that the energy collected by the receiver subsystem be sent to thermal storage. The code was later modified to allow the collected energy to bypass storage for analysis of the Solar One power plant (Alpert and Kolb, 1988). The code is written in FORTRAN77, and input to the code is entered via user-specified text files.

DelSOL

DelSOL is a performance and design code that includes optical and economic analyses. An analytical Hermite polynomial expansion/convolution-of-moments method is used to predict flux images from the heliostats in a computationally efficient manner, typically much faster than either MIRVAL or HELIOS. The code accounts for variations in insolation, cosine forshortening, shadowing and blocking, and spillage, along with atmospheric attenuation, mirror and receiver reflectivity, receiver radiation and convection, and piping losses. The code can be used to evaluate the system levelized energy cost and optimize the field layout, receiver dimensions, and tower height based on these costs. The code is written in FORTRAN77, and input to the code is entered via user-specified text files.

DELSOL3 source code, executable, and sample files

SOLERGY

SOLERGY simulates the operation and annual power output of a solar thermal power plant. It utilizes actual or simulated weather data at time intervals as short as 3 minutes and calculates the net electrical energy output including parasitic power requirements over a 24-hour day. Factors include energy losses in each component of the system, delays incurred during start-up, weather conditions, storage strategies, and power limitations for each component. The original version of SOLERGY (Stoddard et al., 1987) required that the energy collected by the receiver subsystem be sent to thermal storage. The code was later modified to allow the collected energy to bypass storage for analysis of the Solar One power plant (Alpert and Kolb, 1988). The code is written in FORTRAN77, and input to the code is entered via user-specified text files.

SOLERGY source code, executable, and sample files

SAM

System Advisor Mode

Sandia National Laboratories has collaborated with the National Renewable Energy Laboratories to include probabilistic analysis using the SAM system tool.

Computational Fluid Dynamics

ANSYS FLUID

- The CSP team uses the ANSYS Fluid software to research and develop flow processes related to CSP research.

- ANSYS FLUID

MFIX

- The CSP team uses the MFIX tool suite to research flow process and modeling of flow in CSP systems.

- MFIX

Solid Works Flow Simulation

- The CSP team uses the SWFS to design and simulate the flow process in their CSP systems.

- SWFS

Finite Elements Analysis

ANSYS Mechanical

- The CSP team uses this application to model and engineer mechanical components for CSP research.

- ANSYS Mechanical

SolidWorks Simulation

- The CSP team uses this simulation software to simulate and create mechanical components for CSP systems.

SIERRA

Sandia National Laboratories possess a High Performance Computing Platforms known as SIERRA. The CSP team uses the SIERRA platforms for higher fidelity thermal/mechanical simulations of the receiver, heat exchanger, and storage components of a CSP system.

In the same suite as SIERRA, Matlab software is included to perform image processing and modeling.

Due to cyber security restrictions, SIERRA is only for internal use for Sandia National Laboratories personnel.

Computer Aided Design

The CSP team uses SolidWorks software to research and develop all mechanical components for CSP systems.

Work with us

We partner with large and small businesses, universities, and government agencies. With multiple agreement types to select from, partners can access world-class science, engineering, experts, and infrastructure.

Resources

The National Solar Thermal Test Facility is operated by Sandia National Laboratories for the U.S. Department of Energy. The 10-acre research and development and testing facility located in Albuquerque, New Mexico, provides access to unique testing infrastructure which can achieve some of the highest and most controlled solar concentrations in the world. The NSTTF is home to Sandia’s Concentrating Solar Thermal group, which conducts cutting-edge research and development to make CST more efficient, more economical, and more broadly applicable to the nation’s electricity and thermal energy needs.

History

Construction on the NSTTF began in 1976, and the site was commissioned in 1978. Throughout its existence, the facility contributed to research in renewable energy, space exploration, and defense capabilities. The NSTTF led the early development of the first pilot concentrating solar power tower plants: Solar One, a seven-megawatt pilot plant completed in the Mojave Desert in 1981, and Solar Two, an upgrade of the plant in 1995 to ten megawatts of production and three hours of thermal storage using molten salts. The NSTTF contributed to the progression of CST and CSP technologies, from early steam-based solar receivers to molten salt heat transfer and storage media, to next-generation solid particle technologies, which unlock higher efficiencies, lower costs, and longer-duration renewable energy storage. The NSTTF also supported a range of CST technologies including parabolic troughs, dish concentrators, and heliostat field designs from the research and development stage to deployment at the commercial scale.

Today

Thermal Energy Storage recording now available

The National Solar Thermal Test Facility welcomed Scott Hume of the Electric Power Research Institute and Luke McLaughlin of Sandia National Laboratories for the Concentrating Solar Seminar Series session, “Thermal Energy Storage.”

Watch the seminar recording.

Overview and Opportunities for the Generation 3 Particle Pilot Plant

The National Solar Thermal Test Facility’s Concentrating Solar Seminar Series recently presented, “Overview and Opportunities for the Generation 3 Particle Pilot Plant,” an informative discussion regarding completion of the G3P3 tower.

Download the G3P3 presentation or watch the recorded CSP.

Thermal Energy Paradigms

Sandia National Laboratories’ Concentrating Solar Seminar Series featured Dr. Charles Forsberg, of the Massachusetts Institute of Technology (MIT), for his presentation, “Thermal Energy Storage Paradigms.”

Download Thermal Energy Storage Paradigms.

Sandia National Laboratories’ National Solar Thermal Test Facility and Sandia Technical Library developed the world’s first and only digital collection of Concentrating Solar Power related historical documents, dating back to the CSP program’s inception at Sandia in the 1970’s to the present.

This archive includes a significant number of paper-based documents spanning reports, engineering drawings and other media recently converted to digital format. It will provide CSP researchers a unique library of files to help make a larger historical body of CSP documents accessible to the Sandia and global CSP research and development communities.

For more information, contact the CSP Team.

Discover and contact experts through the Earth, Energy, and Environmental Science directory.

Take a Virtual Tour of the National Solar Thermal Test Facility.

Contact

Margaret Gordon, Concentrating Solar Thermal Research and Development manager

megord@sandia.gov

Robert Keene, National Solar Thermal Test Facility manager

rskeene@sandia.gov