Sandia’s geothermal research program employs and develops technologies to reduce the cost and risk of generating electricity from geothermal sources and advance national R&D capabilities. Browse examples of our research below, which include work in rock stimulation, geothermal resource exploration, and subsurface instrumentation sensing and communications.

On this page

Lab Experiments

Position Orientation Timing System (POTS)

Lab-scale explosive testing at the New Mexico Institute of Mining and Technology demonstrates fracture connection between two bored holes in a polymethyl methacrylate block.

Natural formations with the right combination of hot rock and underground water to produce geothermal energy are not located throughout the United States. Because of this, researchers are studying ways to develop enhanced geothermal systems, human-made systems that take a location with hot rock and turn it into a location suitable for producing geothermal power by drilling deep wells and carefully fracturing the hot rock so that water can reach and carry that heat up to the surface to produce power.

When the fracture networks that connect the geothermal injection and production wells are not ideal for the flow of fluid between the two wells, stimulation is required to enlarge the fracture network. Sandia’s position orientation timing effort studied the use of energetics, or explosives, as the means of stimulating the well. The experimental series examined the confluence of initial stress states, interaction with source generated fracture growth, and their orientation of induced discontinuities. In lab experiments, a block sample with energetics placed inside was charged to create fractures between two drilled holes. Acoustic instruments placed on the outer surface of the block were used to detect the position of the acoustic emission generated from a fracture. The project highlighted the viability of using energetics to create fractures and the use of acoustic instruments to detect the location of the growth of fractures. In a field experiment, an array of acoustic instrumentation surrounding the wells could help confirm when stimulation successfully connects the injection and production well.

Field Site Experiments

Enhanced Geothermal System Collaboration (EGS Collab)

Researchers and technicians emplace a packer into a semi-horizontal borehole to monitor rock stimulation and test flow at Sanford Underground Research Facility.

Funded by the Department of Energy’s Geothermal Technologies Office, the EGS Collab unites researchers from multiple national laboratories to increase researchers’ understanding of enhanced geothermal systems. The EGS Collab conducts experiments and test series to bridge small- and large-scale understanding of EGS. Sandia contributes to the effort as an experiment field operation lead and technology developer.

The EGS Collab project performed densely monitored rock stimulation and flow tests at the 10-meter scale in the Sanford Underground Research Facility, located in Lead, South Dakota, to better understand how to safely and successfully implement EGS technology. This project gathered data and observations from the field tests to understand geothermal processes, build confidence in numerical modeling of the processes, and help understand flow and heat transfer in the system. Numerical simulations were used to design the experiments and in turn were validated using the comprehensive monitoring datasets that were collected during each field experiment.

Basin and Range Investigations for Developing Geothermal Energy (BRIDGE)

A helicopter carries electromagnetic instrumentation for a geologic survey.

Resistivity imaging is a powerful method for geothermal energy resource exploration. Led by Sandia and funded by the Department of Energy’s Geothermal Technologies Office, the BRIDGE research project is developing a workflow to increase the efficiency and efficacy of discovering and characterizing hidden geothermal energy systems in the Basin and Range Province of the western United States. Resistivity methods are sensitive to the attributes of geothermal systems and thus are a crucial part of the workflow proposed and used by the BRIDGE project team. The effort uses a helicopter-borne electromagnetic surveying method for rapid, regional-scale imaging of the shallow subsurface to detect resistivity signals associated with hydrothermal outflow features, such as a clay cap and/or hydrothermal alteration. The data and workflow generated from this project will be made publicly available to facilitate the discovery and characterization of hidden geothermal resources.

Developing Subsurface Tools & Sensors

Drilling and operating geothermal wells requires scientists and operators to characterize the well, collecting information to understand its features such as the nearby rock and fluid properties. This characterization often includes measuring aspects of the drilling process and well, such as drilling bit forces, well temperatures, pressures, chemistry, fracture formation, and well integrity. Sandia’s geothermal research program develops various technologies to help the geothermal industry obtain characterization data more efficiently and reliably. Some examples of the different subsurface technologies developed at Sandia are listed below.

260˚ C Pressure Temperature Spinner (PTS) Logging Tool

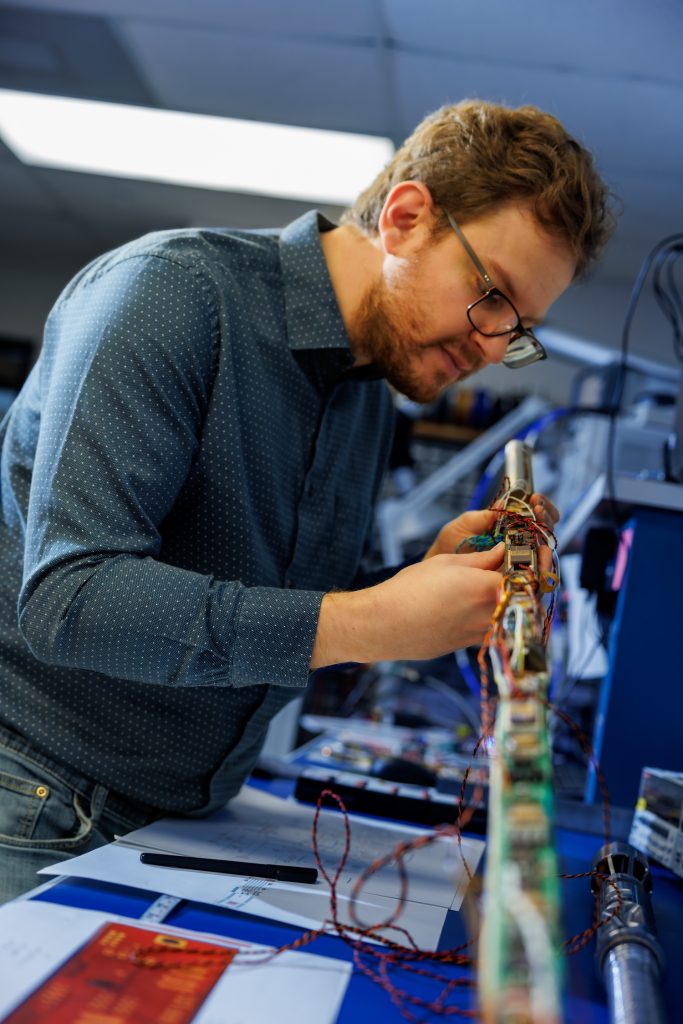

A member of Sandia’s geothermal research team inspects the pressure temperature spinner (PTS) tool, which has a temperature functionality of 260˚C.

A Sandia-developed Pressure Temperature Spinner Collar tool can operate at 260˚C while at pressures reaching above 10,000 psi. The tool uses commercially available high-temperature electronic components. Unique to the tool, Sandia’s custom application-specific integrated circuit (ASIC) adds additional processing and programming function for the HT83C51 microcontroller. This tool was also designed to locate the collars along the length of the well to improve accuracy of the depth measurements. The tool is also upgradable to add additional features such as chemical measurements.

High-Temperature, High-Pressure Chemical Sensors

An inspection is conducted of the custom high temperature, high pressure pH sensors.

For the past decade, Sandia has been developing chemical sensors that can operate above 225˚C and 3000 psi. Three types of sensors have been developed for these conditions: chloride, iodide, and pH sensors. Currently, the pH sensor is under development to operate up to 5000 psi and 300˚C.

Acoustic Communications and Power via Well Casing

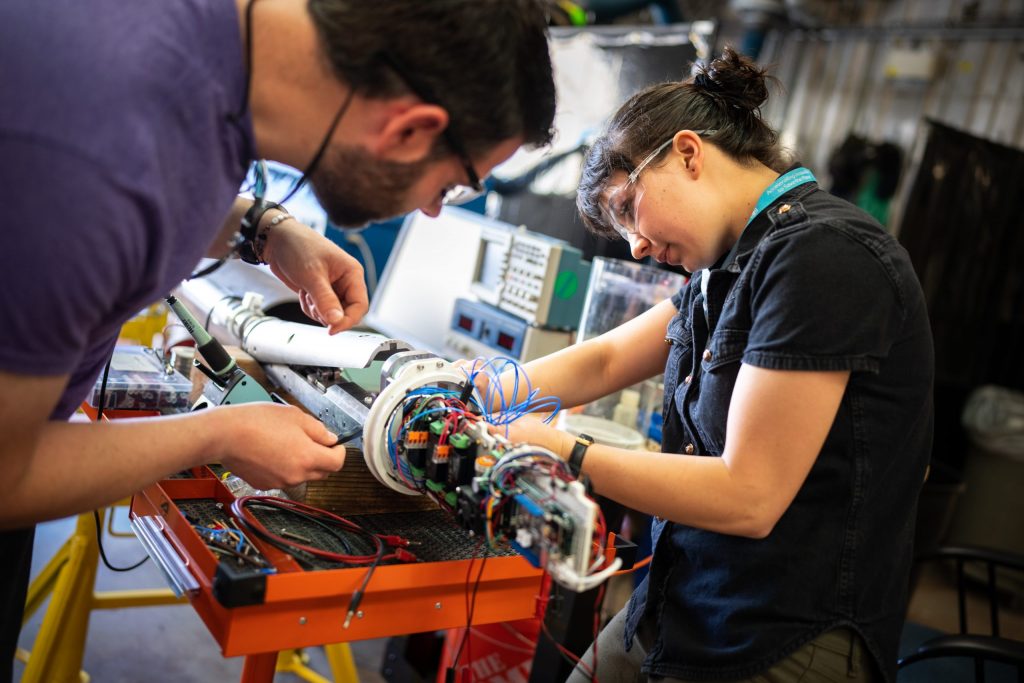

Team members assemble an acoustic tool to demonstrate acoustic communication and power through a subsurface well casing.

Sandia is developing a new way to power and communicate with downhole equipment such as subsurface instrumentation embedded with CO2 sensors used to monitor for leaks. Currently, sensors installed for long-term use require the installation of conductors or fiber, which can create a leak path. Sandia has been developing a novel solution that instead uses the casing string as an acoustic waveguide to provide wireless power and communications to downhole sensors. The technology uses acoustic energy from the surface that propagates through the casing to be harvested and converted to electrical energy in a downhole instrument. The harvested energy would be stored in an energy bank and then used to query the sensors and transmit the data to the surface on an acoustic carrier waveform imbedded with data. This approach would enable long-term sensor deployment that can be interfaced from the surface without transmission lines, reducing the risk of wellbore leakage.

Acoustic Measurement While Drilling (MWD)

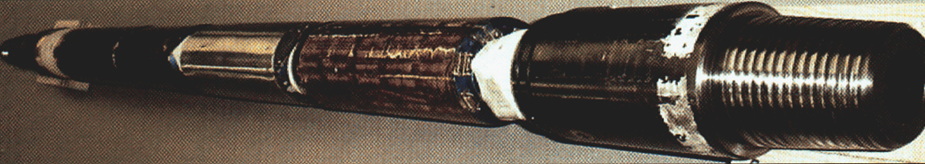

A geothermal measurement while drilling (MWD) tool designed for acoustic communications through the drilling string during drilling operations.

When drilling a geothermal well — which can reach depths of 10,000 feet — operators currently use traditional methods that offer little sense of what is happening downhole. Better diagnostics and information could increase operators’ awareness and ability to monitor the conditions on the drill bit and string. Mud-pulse telemetry (subsurface instrumentation that pulses the fluid to relay data to the surface) is a common means for data communications but is limited to excessively slow data rates. Sandia developed a tool that uses acoustics to transmit data across the pipe string for communications with data rates ten times faster than data rates for mud-pulse communications.