Sandia’s geothermal research program sustains multiple capabilities that reduce the cost and risk of research for novel geothermal technology while advancing national R&D capabilities. Geothermal capabilities available at Sandia span high temperature, pressure, and vibration testing; fabricating new components and systems; and evaluating drilling components. Browse our unique capabilities below.

On this page

Dynamometer Test Station

At the dynamometer test station, a team member installs a customized, hydraulic downhole motor for evaluation on the high torque dynamometer test station.

The Dynamometer Test Station is used to demonstrate and evaluate developmental downhole motor concepts. Current downhole motors (positive displacement motors) are not capable of drilling at high temperatures due to the material limitations imposed by the elastomeric stator used within the power section. Developmental motor concepts are being developed that do not rely upon designs constrained by low temperature material properties. The Dynamometer Test Station can evaluate critical functions of developmental motor concepts in scaled settings on representative drilling fluids. Then, the results can be used to advance overall motor designs for testing in a more prototypical drilling configuration.

High-Temperature Electronic Packaging

A researcher reviews high temperature printed circuit boards for soldering through the multistage, reflow Sikama oven.

To push for higher temperature (HT) operation of electronics while also improving reliability, various unique capabilities are required for the packaged components to survive at temperatures above 200˚C. These elevated temperatures even require special printed circuits boards and integrated circuits (ICs). Sandia specializes in packaging off-the-shelf silicon-on-insulator ICs onto Rogers or polyimide materials using new research for bonding to ceramic. These abilities allow the fabrication of electronic systems designed for 300˚C operation.

High-Temperature, High-Pressure, & Vibration Testing

A researcher evaluates high temperature, high pressure chemical sensors within a 5,000 psi, 300 ˚C Parr autoclave.

Our geothermal research program also offers multiple methods to evaluate electronic components and systems at elevated temperatures. Sandia’s capabilities offer simultaneous high-temperature and high-pressure testing or vibration testing while under high-temperatures. The available ovens operate at temperatures of 250˚C, 350˚C (this includes our large volume oven), and 900˚C. Vibration and high temperature evaluation can also be conducted with our 110 lbf and 500 lbf shaker systems, which are capable of 6,500 Hz and 4,500 Hz, respectively. The shaker systems can also run temperature and vibration profiles. An autoclave, capable of 5,000 psi and 300˚C, allows for evaluation of components under these conditions. This system is essential for evaluating sensors that are exposed directly to the geothermal fluid.

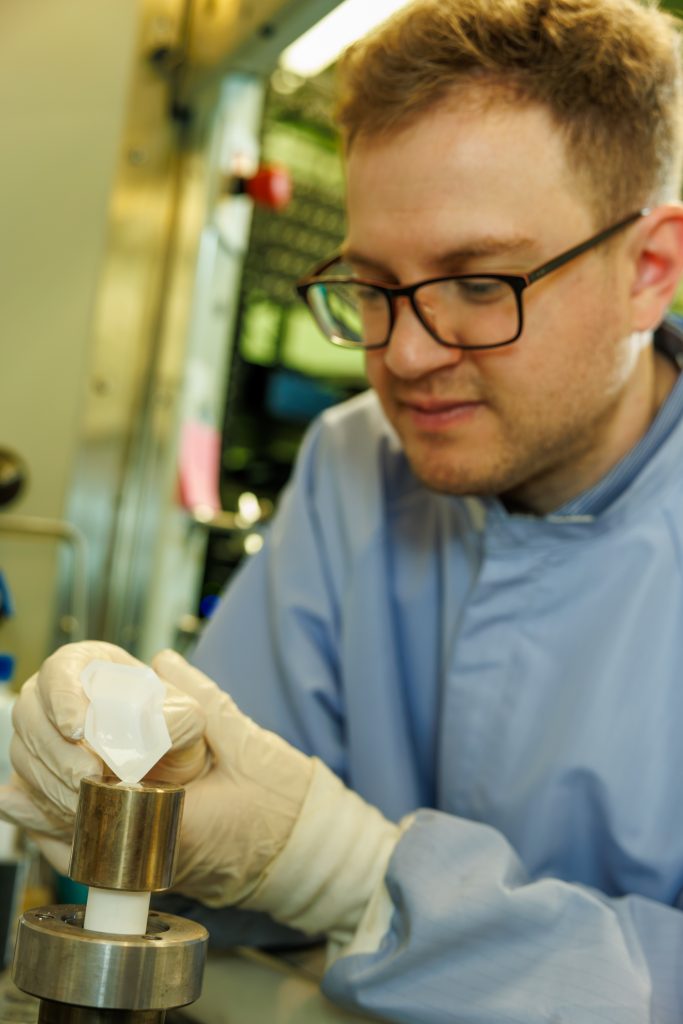

High-Pressure, High-Temperature Rheometer

As part of Sandia’s geothermal research and development program, research teams can evaluate cement samples within a high pressure, high temperature rheometer for characterizing the rheologic properties.

To evaluate the viscosity of drilling fluids at high temperatures, Sandia use a coaxial rotational high -pressure (HP) and high-temperature rheometer, M7500 rheometer model. The rheometer can measure various rheological properties of fluids at conditions of up to 600 RPM, 207 MPa, and 316˚C. Additionally, the M7500 rheometer comes equipped with two separate components that allow for the testing of cement’s rheologic properties and the linear and volumetric swelling of solids at high pressures and temperatures.

Chemical Sensor Development & Fabrication

A researcher assembles a high temperature, high pressure pH sensor within a fume hood.

To evaluate geothermal wells, specialized sensors are required which can survive harsh temperatures, pressures, and fluid chemistry. Sandia’s geothermal research program can work with various hazardous chemicals to develop and evaluate specialized sensors. Available to the program’s researchers are a chemical fume hood, automated powder sieve, automated powder grinder, pellet press, and other basic chemical working equipment. Sandia’s Advanced Materials Laboratory offers advanced chemical tools for safely handling, evaluating, and processing hazardous chemicals — an additional resource when developing new geothermal technologies.

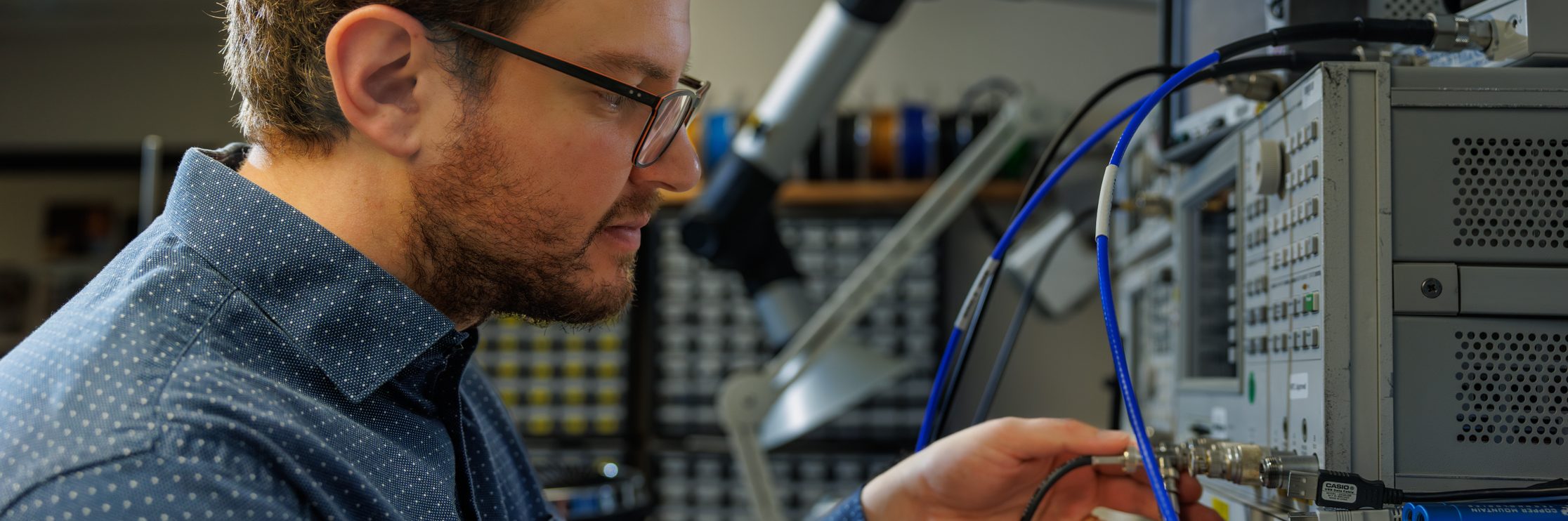

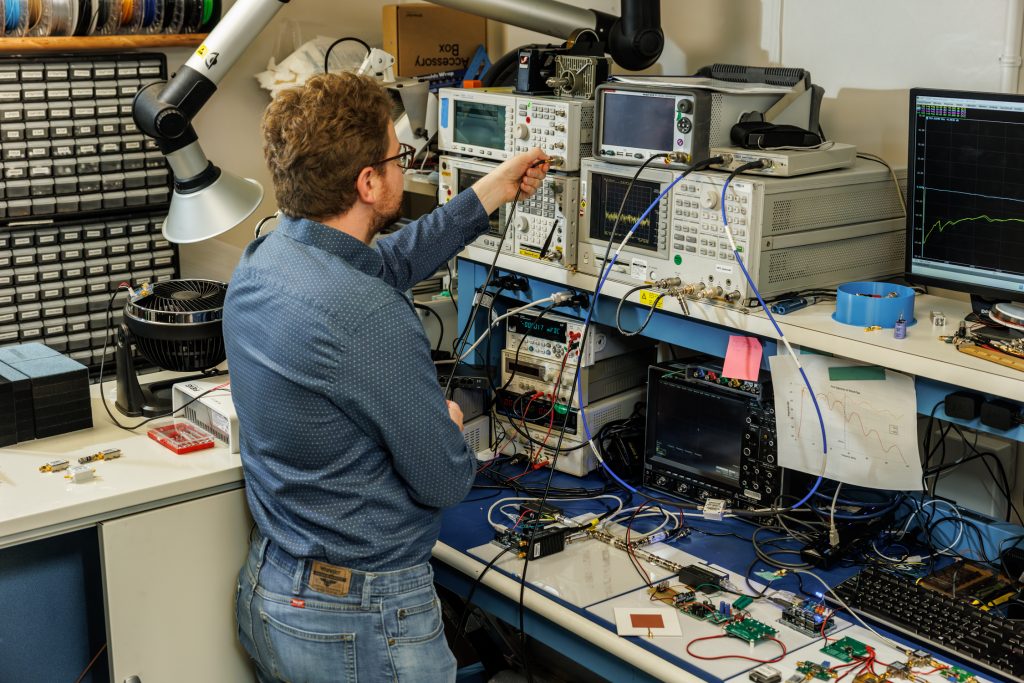

Electronics Radio Frequency Evaluation

Using spectral analyzers and vector network analyzers, Sandia can help evaluate and characterize RF equipment used for communications in geothermal technologies. Here, a team member evaluates the performance of a 902–928 MHz RFID reader and sensors.

For Sandia’s geothermal research program, radio frequency (RF) equipment is used for applications that require free-space communications, cable communications, or other forms of RF communication. Sandia’s geothermal research program has multiple spectral analyzers, signal generators, and vector network analyzers, all of which can operate in the GHz. Among other applications, this equipment can be used to characterize logging tool wirelines, amplifiers, isolators, and filters — or even for wireless communications through cement.

Shallow Directional Drilling

Logging-while-drilling (LWD) tools have embedded electronic systems that help the operator assess the direction and location of the drill bit in the subsurface. Here, the team operates a Ditch Witch to evaluate a custom LWD tool.

Logging-while-drilling (LWD) tools can help equipment operators identify and record the temperature, pressure, fluid chemistry, direction, and location of drill bits during operation to improve drilling accuracy and targeting. Our shallow directional drilling capabilities allow LWD tools to be evaluated under subsurface operating conditions. Specifically, Sandia has the facilities and expertise to evaluate embedded electronic systems, sensors, communications, and power in LWD tools under high vibration and rotation.

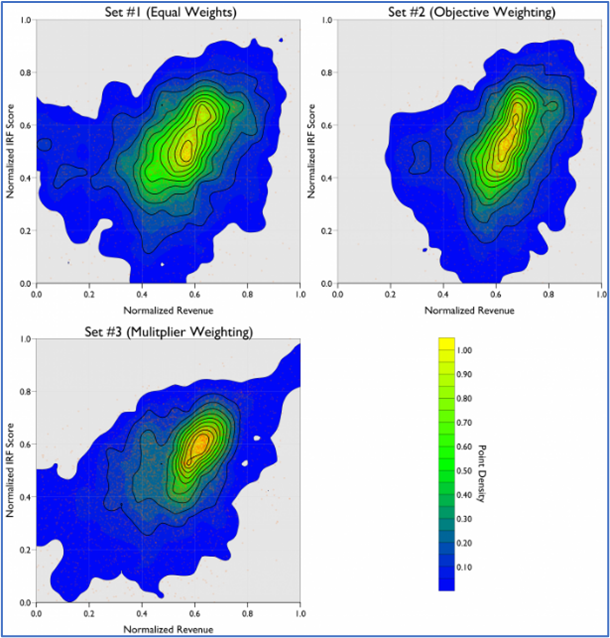

Computational Modeling

A computer model of a geologic location.

Modeling plays an important role in understanding and predicting geothermal system performance and sustainability. Using advanced numerical methods and massively parallel high-performance computing, Sandia can simulate processes important to geothermal development and energy production across a wide range of scales. As part of our geothermal research program, we can simulate thermal, hydrological, mechanical, and chemical processes at pore- and fracture scales and provide project-scale analyses of geothermal projects’ physical and economic performance.