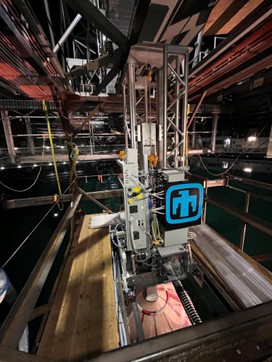

The WaveBot, a scale-model wave energy converter (WEC), bobs up and down in the water as researchers cluster around a row of monitors in the control room of the largest wave tank in the United States. This is the WaveBot’s fourth trip to the U.S. Naval Surface Warfare Center, Carderock Division Maneuvering and Seakeeping Basin (MASK) in Bethesda, Maryland. The goal for this trip is to validate and explore how different elements of WEC design interact with each other, a concept known as co-design, and impact power output as well as provide proof of concept for a custom motor drive.

The Sandia National Laboratories Water Power Technologies group has spent the last decade applying their multidisciplinary expertise to bridging the gap between marine energy concepts and applications. The WaveBot plays a crucial role in these efforts. Originally built to study control algorithms, the WaveBot has since been used to study modeling, system identification, control, device design, and numerous other applications. The WaveBot work is sponsored by the Department of Energy’s Water Power Technologies Office. Sandia’s Water Power researchers often partner with industry and academia to refine and test designs and concepts as part of our efforts to make marine renewable energy a feasible and cost-effective part of the nation’s energy portfolio.

The most recent MASK test used the WaveBot to assess how a magnetic spring developed by Portland State University would perform under specific wave conditions. According to Sandia researcher Ryan Coe, “some of the results were exactly as expected. Other results were a little surprising initially, but quickly connected with our theories and helped to clarify key concepts.”

The test campaign also provided valuable information about the motor controller, power measurements, bi-conjugate impedance matching, and co-design. Research and design engineer Giorgio Bacelli, another member of the testing team, said that “based on the results of this test, we are confident that we now have a very good picture of the power flow through these machines, from source (waves) to user (load). This will result in a significant improvement in the design process and performance improvement.”

In addition to Coe and Bacelli, Sandia’s team for this test campaign included Damian Gallegos-Patterson, Dominic Forbush, Jantzen Lee, Robert Crandell, Tim Donnelly, Steven Spencer, Kevin Dullea, Carlos Michelén, and Daniel Gaebele.

Members of the research team will host a webinar with a Q&A session on March 26, 2024, to share their findings and respond to questions. Register to attend the webinar or view recordings of archived webinars.

February 21, 2024